I-CNC (Amanani wenombolo yamanani)) ubuchwepheshe bokukhiqiza budlala indima ebalulekile ekwenziweni kwanamuhla, futhi izindlela zayo zokucubungula ezisebenzayo zilethe izinguquko ezinkulu ezimbonini eziningi. Kodwa-ke, njenganoma iyiphi inqubo yokukhiqiza, kunesici sezindleko esihilelekile nge-CNC Facerication. Lo mbhalo uzokwethula izici eziphambili zezindleko zokubukelwa kwe-CNC ukuze uqonde kangcono ezomnotho nezinselelo.

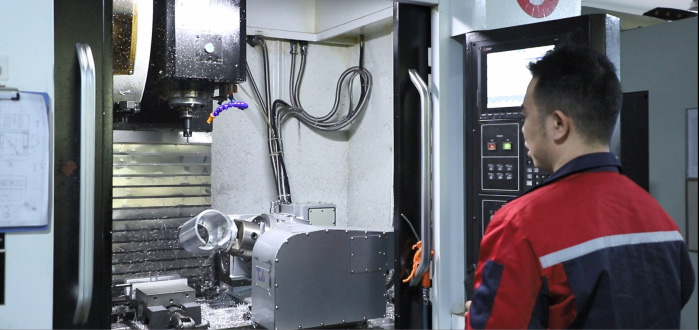

Okokuqala, izindleko zokukhiqizwa kwe-CNC zithintwa yimishini namathuluzi. Amathuluzi womshini we-CNC angumshini oyisisekelo wokucubungula okuzenzakalelayo, futhi amanani awo ajwayele ukubiza. Izinhlobo ezahlukahlukene namasayizi wamathuluzi womshini we-CNC anamabanga ahlukile, asuka emishini emincane aya emishinini emikhulu ehlukahlukene, futhi amanani awo angahlukahluka kakhulu. Ngaphezu kwalokho, eminye imishini yokuhambisa namathuluzi adinga ukucatshangelwa, njengabasiki, ama-jigs kanye namathuluzi wokulinganisa, futhi angezelela izindleko zokukhiqiza.

Okwesibili, izindleko zokukhiqizwa kwe-CNC zihlobene nokukhethwa kwezinto ezibonakalayo. Izinto ezahlukahlukene zinezici ezahlukahlukene nobunzima. Ngokucutshungulwa kwe-CNC, ezinye izinto zokwenziwa zingadinga amathuluzi angenakuvikelwa kakhudlwana, izindlela eziyinkimbinkimbi zokucubungula, noma izidingo zenqubo ezixakile, ezizokhulisa izindleko. Ama-alloys asebenza kakhulu, ama-composites, kanye nezinto ezikhethekile ngokuvamile zibiza kakhulu, ngenkathi izinto zensimbi (ezifana ne-aluminium, insimbi, ithusi, njll.) Zivamile futhi zinomnotho.

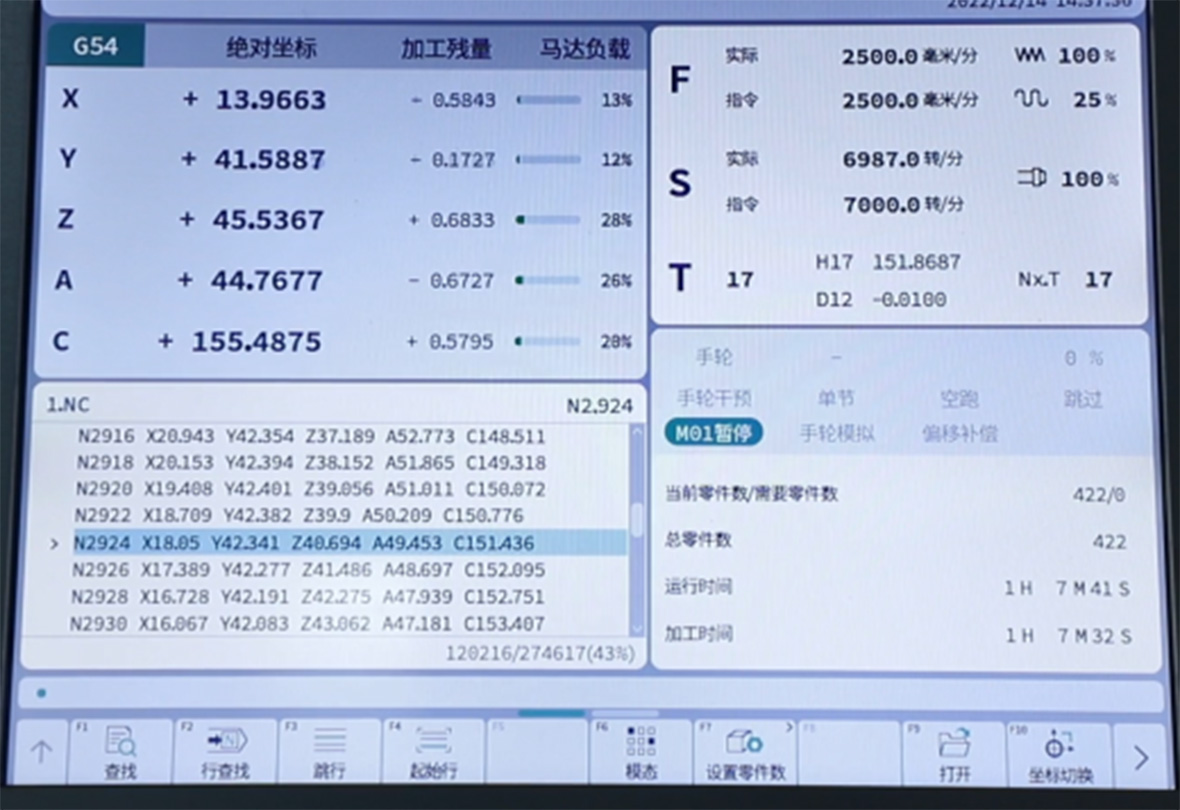

Okwesithathu, uhlelo kanye nokwakhiwa kuyizinto ezibalulekile zezindleko ekukhiqizeni i-CNC. Ekukhiqizeni i-CNC, ukubhala i-G Code noma amafayela e-CAM alungele amathuluzi omshini kubalulekile. Lokhu kudinga ochwepheshe ngolwazi lobuchwepheshe kanye nesipiliyoni ekuklameni komkhiqizo kanye nokuzimisela indlela yokucubungula ku-software yokudweba isoftware kanye nohlelo. Ubulukhuni bohlelo kanye nokwakhiwa kuncike ebukilini kanye nezidingo zomkhiqizo, ngakho-ke imikhiqizo eyinkimbinkimbi imvamisa ivame ukuhlela izinhlelo eziphakeme kanye nezindleko zokwakheka.

Ngaphezu kwalokho, ukukhiqizwa kwe-CNC kuhlanganisa nakho ukulungiswa kwemishini nezindleko zokusebenza. Ukuqina nokunemba kwamathuluzi omshini kudinga ukulungiswa njalo kanye nokushelela ukuqinisekisa ukusebenza kwawo okujwayelekile nokucutshungulwa okunembile. Izindleko zokusebenza zifaka phakathi izici ezinjengokusetshenziswa kwamandla, ukushintshwa kwamathuluzi nokuhamba, futhi lezi zindleko zincike ngosayizi nobunzima benqubo.

Kumele kwaziwe ukuthi yize ukukhiqizwa kwe-CNC kungabandakanya ukutshalwa kwezimali okuphezulu kanye nezindleko zokuqalisa, ukunemba kwayo, ukusebenza kahle nokuphindaphinda kungaletha ukubuyiselwa okungcono kwezomnotho. Nge-automation kanye nokusebenza okuqondile, ukukhiqizwa kwe-CNC kunganciphisa ukusebenza kwezandla futhi kunciphise amaphutha abantu, ngaleyo ndlela kuthuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Ngamafuphi, ukukhiqizwa kwe-CNC kubandakanya izici eziningi zezindleko. Imishini namathuluzi, Ukukhethwa kwezinto ezibonakalayo, uhlelo kanye nokwakhiwa, ukugcinwa kanye nokusebenza kuyizinto eziphambili ezithinta izindleko zokukhiqiza i-CNC. Ukuqonda lezi zinto kungasiza ekuhloleni kangcono i-Economics kanye nokwenzeka kwe-CNC Facerication futhi wenze izinqumo ezinolwazi zabakhiqizi namabhizinisi. Ngokuthuthuka okuqhubekayo kobuchwepheshe kanye nokuncintisana emakethe, singalindela ukuthi izindleko zokukhiqiza ze-CNC zizokwenziwa futhi zincishiswe ukuze zihlangabezane kangcono nezidingo ezahlukahlukene zokukhiqiza.

Isikhathi Sokuthumela: Oct-23-2023