24h

Izingcaphuno ezisheshayo

Izinsuku eziyi-10

Isikhathi esiholayo

I-0PC

I-MOQ

0.010 mm

Ukubekezelela

Izinsizakalo zethu zokufa kwe-Deep

Uma unezidingo zezingxenye zensimbi yangokwezifiso, i-CNCJSD ingumenzi wenkonzo wokudla ofa ongasiza. Kusukela ngo-2009, sibambe iqembu lethu lezobunjiniyela kanye nemishini kwizinga eliphakeme lokuhambisa izingxenye eziqinile nezihlala isikhathi eside kanye nama-prototypes. Ukuqinisekisa ikhwalithi edumile, sisebenzisa inqubo eqinile yokufa okufayo eqinisekisa ukuthi izidingo zakho zangokwezifiso ziyahlangabezana. Lezi izinhlobo ezimbili zamakhono okufa afe.

IChamber eshisayo Die Casting

I-Hot Chamber Die Casting, eyaziwa nangokuthi i-GooseNeck Casting, inqubo esheshayo esheshayo nomjikelezo ojwayelekile wokuphonsa imizuzu eyi-15 kuya kwangama-20. Ivumela ukukhiqizwa okuphezulu kwevolumu yezingxenye eziyinkimbinkimbi.

Inqubo ilungele i-zinc alloy, lean alloys, ithusi namanye ama-alloys anendawo ephansi yokuncibilika.

Igumbi elibandayo lifa

Inqubo ebandayo yokufa kweChambor Diest iyinqubo ebaluleke kakhulu esiza kakhulu ukunciphisa inani lokushisa nokuxazulula inkinga yokugqwala ekuphangelini komshini kanye nezinto ezihlobene.

Inqubo isetshenziselwa ikakhulukazi ama-alloys ngamaphoyinti aphezulu ancibilikayo, njenge-aluminium, i-magnesium, amanye amathusi, kanye nama-alloys amnandi.

Kungani Khetha i-RapidDierct for Die Casting Parts

Ukukhetha okubanzi

Sinikezela ngezindlela ezahlukahlukene zezinto ezibonakalayo, izinketho zokuqeda okungaphezulu, ukubekezelelana nezinqubo zokukhiqiza zezingxenye zakho zokudla ezifa. Ngokusekelwe kwizidingo zakho zangokwezifiso, sikunikeza izingcaphuno ezahlukahlukene kanye neziphakamiso zokukhiqiza ukuze ukwazi ukuthola indlela yomuntu ngamunye kanye nesixazululo esingesibi kakhulu.

Isitshalo esinamandla nezindawo

Sisungule izitshalo zethu eziningi eChina ukwenza isiqiniseko sokuthi izingxenye zakho zokuphonsa zenziwa ngokusebenza kahle kanye nesikhathi esiholela esisheshayo. Ngaphandle kwalokho, amakhono ethu okukhiqiza asebenzisa ngokunenzuzo izindawo ezifika esikhathini ezizenzakalelayo ezingasekela avestment zamaphrojekthi akho okufa adayiwe, yize ama-design awo ankimbinkimbi.

Ukulawulwa kwekhwalithi okuqinile

Siyinkampani ye-ISO 9001: 2015: 2015 izibophezele ekunikezeni ngokuqondile izinsizakalo zokuphonsa. Iqembu elizinikezele lobunjiniyela le-CNCJSD lisebenza ngokuhlolwa kwekhwalithi okuqinile ngezigaba ezahlukahlukene zenqubo yokukhiqiza: Ukukhiqizwa kwangaphambili, ekukhiqizeni i-athikili yokuqala nokulethwa ukuze kuqinisekiswe ukuthi izingxenye ezisezingeni eliphakeme zenziwa.

Isithanga lokucaphuna online

Ipulatifomu ye-Advanced Online yokucaphuna ukuze ikunikeze amandla okulayisha amafayela okuklama futhi uthole isilinganiso esisheshayo sezingxenye zakho ze-Die Cast Metal nganoma yisiphi isikhathi noma kuphi. Uhlelo lokulandela ipulatifomu yethu likuvumela ukuthi uqaphe yonke imiyalo yakho nezingcaphuno futhi ubuke isigaba ngasinye senqubo yokukhiqiza uma ubeka ama-oda. Lokhu kwenza inqubo ye-oda icace futhi icace.

Die uphonsa kusuka ekuhlolweni kokukhiqizwa

I-Die Casting iyindlela ephumelela kakhulu yokukhiqiza ama-prototypes aphezulu asezingeni eliphakeme nezingxenye ezincane ze-batch, okwenza kube ukukhetha okuhle kwezicelo eziningi. Iqembu lethu lilapha ukukusiza ekufezekiseni izinhloso zakho zokukhiqiza ngokunikeza amasevisi wokudla ochwepheshe.

Prototyping

Kanye nendlela engabizi futhi ephumelelayo yokwakha ama-prototypes asezingeni eliphakeme. Le nqubo isebenzisa amathuluzi abiza kancane, okwenza kube yindlela esebenza ngempumelelo yokukhiqiza ama-prototypes ngezinto ezahlukahlukene nezinguquko zokuklama.

Ukuhlolwa Kwemakethe

Sikusiza ukudala imikhiqizo yokudla efa ilungele ukuhlolwa kwemakethe kanye nokuhlolwa kwabathengi, amamodeli emqondo, nokuhlolwa komsebenzisi. Izinsizakalo zethu zokudla okufa zikuvumela ukuthi ufake izinguquko ngokushesha ukuze kwethulwe okunye nokuvulwa kwemakethe.

Ukukhiqizwa okufunwayo

Izingxenye ze-Die Cast ziyizinketho ezinhle kakhulu zokukhiqizwa ngokwezifiso nokuqala. Ungabiza ngempumelelo ikhwalithi yomkhiqizo ngaphambi kokuqala ukukhiqizwa okugcwele.

Die casting izindinganiso zobuchwepheshe

| Ubukhulu | Amazinga |

| Isisindo esiphansi esilinganiselwe | 0.017 kg |

| Isisindo Esibanzi Esiphezulu | 12 kg |

| Ubukhulu obuncane bengxenye | ∅ 17 mm × 4 mm |

| Ubukhulu obuningi obukhulu | I-300 mm × 650 mm |

| Ubuncane obuncane bodonga | 0.8 mm |

| Ubukhulu obukhulu bodonga | 12.7 mm |

| Ikilasi lokubekezelela lokuphonsa | ISO 8062 ST5 |

| Ubuncane be-batch | Ama-PC ayi-1000 |

I-Die Casting Surface Perses

Ukusebenza ngemuva nokuqeda isinyathelo sokugcina sokuqapha okufa. Ukuqedwa kungafakwa ukuze kususwe iziphambeko zangaphandle zezingxenye, zithuthukise izakhiwo zemishini noma zamakhemikhali, futhi zithuthukise ukubukeka kwezimonyo '. Kunezinhlobo eziyisithupha zezinketho zokuqeda indawo yokufa.

Izicelo zokudla ezifa

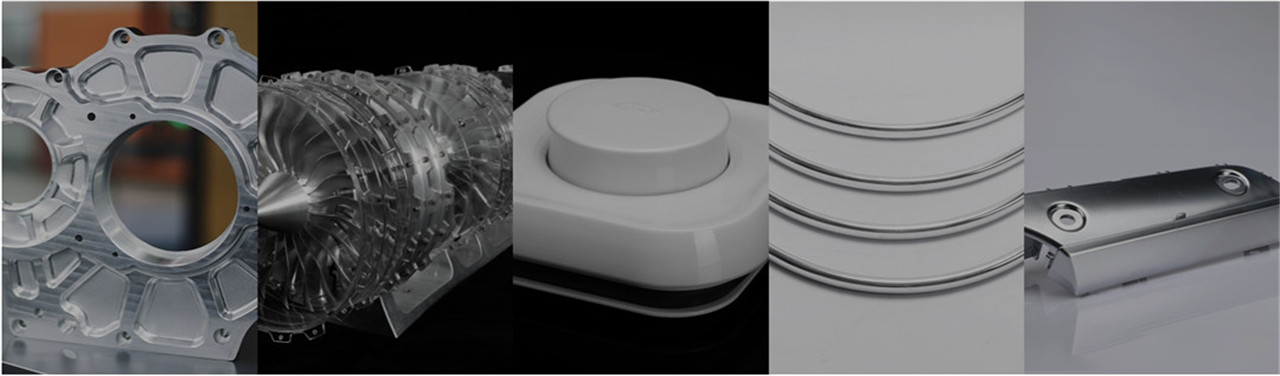

I-Die Casting iyindlela yokukhiqiza eguquguqukayo, futhi idlala indima ebalulekile ekwakheni nasekukhiqizeni imikhiqizo eminingi yanamuhla, kusuka ezingxenyeni zokwakheka ze-aerospace kuya kwezindawo zikagesi. I-CNCJSD ihlinzeke ngezixazululo ezintsha zokukhiqiza izicelo ezahlukahlukene zezimboni. Sinikeza izingxenye ezisezingeni eliphakeme ngamanani entengo yokuncintisana ukuze ukwazisa amakhasimende kulezi zimboni ezilandelayo:

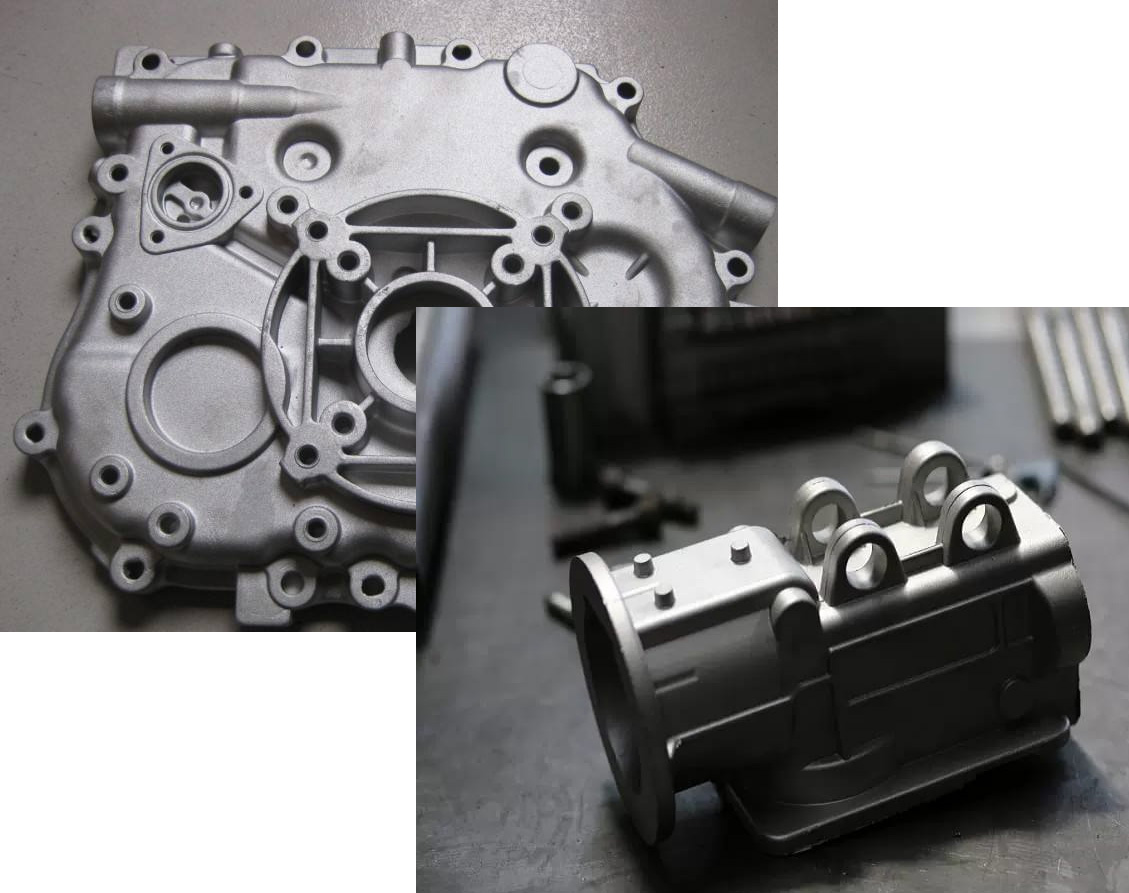

Izimoto ezihamba ngezimoto: Njengomkhiqizi wezimoto ezifa, sisebenza ngokukhethekile ekwenzeni izingxenye zemoto njengamagiya, amasilinda, ama-elengayo, amacala okudlulisa, izingxenye ezincane zenjini, kanye nezingxenye zogandaganda be-lorn kanye nengadi.

Imboni ye-Aerospace: I-Magnesium ne-Aluminium Pressure die casting technologies kusuka ngokunemba kwenkonzo yokuqapha ye-die kungakhiqiza izingxenye ezinhle eziqinile ezinokumelana okukhulu kokugqwala.

Izakhi zombani: Inkonzo yethu yokudubula yokufa nayo yenzelwe izindlu zikagesi, i-Die Cast Heath Sights, kanye nezakhi eziningi eziningi.

Imikhiqizo yezentengiselwano neyeMthengi: Siphinde sakha izingxenye zentengiso kubandakanya izinduku zeCompressor kanye nezinduku zokuxhuma, ukushiswa kokushisa, izingxenye zezindlu zesikhumba, amamitha.

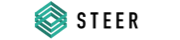

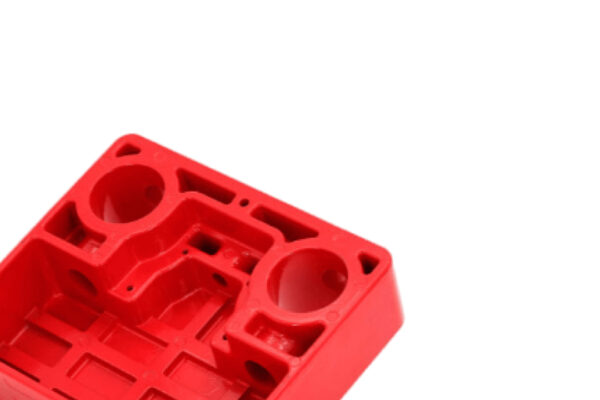

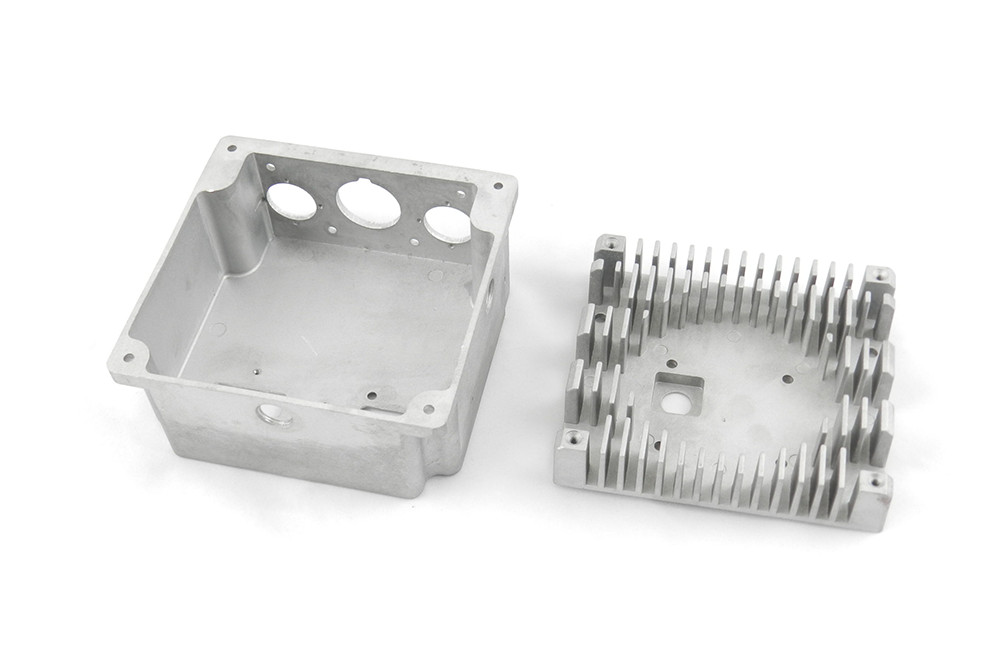

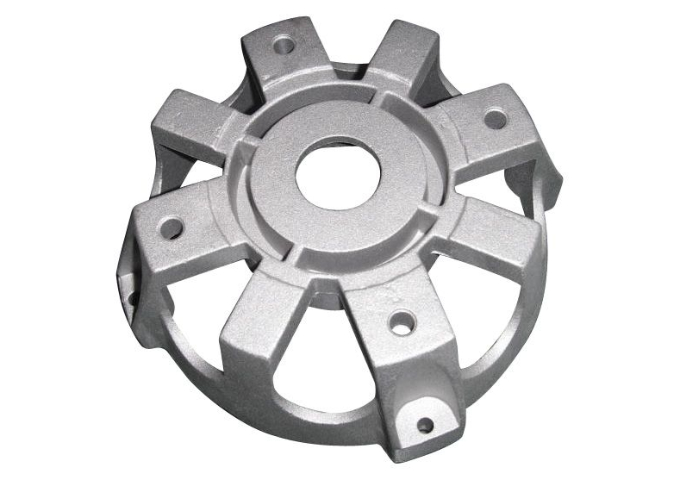

Igalari yezingxenye zokudla ezifa

Bheka igalari yethu ebanzi ekhombisa ukunemba okufa kumakhasimende ethu abalulekile.

Bona ukuthi amakhasimende ethu athini ngathi

Amagama wekhasimende anomthelela omkhulu kunezimangalo zenkampani - futhi ubone ukuthi amakhasimende ethu anelisekile asho maqondana nokuthi sifeza kanjani izidingo zawo.

Ngisebenzise izinsizakalo ze-CNCJSD Die Casting Services kusukela ngoJuni 2019. Bebelokhu bephendule, besebenzayo, futhi nabaqeqeshiwe ekuphenduleni izicelo zami. I-CNCJSD isebenza ekuletheni imiklamo yami yangempela, futhi yonke ingxenye idlula okulindelwe.

Inkampani yethu yayala i-aluminium die casts esidinga inqubo yomhlangano kusuka ku-CNCJSD. Sinezidingo eziqondile zokukhiqiza, okuyi-CNCJSD ekwazi ukuhlangana nazo. Bahlinzeka ngempahla esezingeni eliphakeme ngenani elifanele. Sizoqhubeka sisebenzisa i-CNCJSD, futhi sikweluleka ngokuqinile noma iyiphi enye inkampani edinga ukuthi uDiecast wenze okufanayo!

Xhumana ne-CNCJSD nganoma yisiphi isidingo sakho sokudla se-aluminium die. Sisebenzisa umugqa wabo wokukhiqiza wezinto ezinezimoto. Baqinisekisa isikhathi eside semikhiqizo yamakhasimende ethu. Inkonzo yabo yamakhasimende kwakulula ukuyifinyelela, futhi asizange sihlangabezane nanoma yiziphi izinkinga futhi sizoqhubeka sisekela futhi siyabhekisa.

Imishini yethu ye-CNC yezicelo ezahlukahlukene zezimboni

I-CNCJSD isebenza nabakhiqizi abaholayo abavela ezimbonini ezahlukene ukusekela izimfuno ezikhulayo futhi baqondise ukuthengiswa kwabo. I-digitalization yezinsizakalo zethu ze-CNC Machcing Services isiza abakhiqizi abaningi ngokwengeziwe balethe umbono wabo kwimikhiqizo.

Ama-alloys asetshenziselwa ukwenza izingxenye zokudla die

Izinsimbi ezingezona ze-Ferrous ezinamazinga okushisa aphansi aphansi zingasetshenziselwa inqubo yokudubula efa, njenge-aluminium, i-zinc, i-magnesium, ukuhola, ithusi. Kepha ezinye izinsimbi ezingajwayelekile nezenhlamvu kungenzeka. Lokhu okulandelayo kuzochaza izakhiwo ze-Dis evame ukusetshenziswa ngokudina okusisebenzisayo iningi lezingxenye.

I-Aluminium Alloys

I-Aluminium Die Casting Alloy yensimbi engasindi kahle inensimbi ye-silico, ithusi, i-magnesium, i-iron, i-banganese ne-zinc.

Ibonisa amandla aphezulu ashisayo, ukuqhutshwa kukagesi, ukusebenza kokusika, kanye nokuqothuka okuqondile okuqondile, okwenza kube nokusebenza okuhle kakhulu kanye nekhono lokugcwalisa.

Ngaphezu kwalokho, ama-alloys we-aluminium angagcina izakhiwo ezinhle zemishini ngaphansi kwamazinga okushisa aphezulu noma aphansi ngenxa yobuningi babo namandla aphezulu.

I-Aluminium Alloys ejwayelekile esetshenziswa:

I-A380, A360, A390. A413, ADC-12, ADC-1

Ama-Zinc Alloys

Izinto eziphambili ezingezwe kuZinc Die Casting Alloy yi-aluminium, yethusi kanye ne-magnesium.

Inikeza ukuphela okuhle ngaphandle kwesidingo sokucubungula kwesibili. Okusemqoka, i-zinc alloy ibiza kakhulu futhi inamandla kunezinye izinto eziqhathaniswa.

Futhi, ine-fluidity kanye nokuphikiswa kokugqwala ngakho-ke isetshenziselwa ikakhulukazi amamitha wokudla okufa, izingxenye zezimoto, nezinye izingxenye eziyinkimbinkimbi zensimbi.

I-Zinc Alloys evame ukusetshenziswa:

UZamak-2, uZamak-3, uZamak-5, uZamak-7, Za-8, Za-12, za-27

Ama-magnesium alloys

Izici eziphambili ze-Magnesium Die Casting Alloy yi-aluminium, i-zinc, i-manganese, i-cersium, nenani elincane le-zirconium noma i-cadmium encane.

Inezinzuzo zamandla aphezulu, i-viscosity ephansi, uketshezi oluhle, ukumelana okukhulu kokugqwala nokugcwaliswa okulula kwama-callities ayinkimbinkimbi.

I-Magnesium Alloy ingasetshenziselwa ukukhishwa kokufa kwezingxenye zokubumba nezincane ezidongeni ngaphandle kwemifantu eshisayo.

I-Magnesium Alloy evame ukusetshenziswa:

I-AZ91D, AM60B, AS41B

Izingxenye zekhwalithi zenziwe lula, zishesha