Vacuum Casting for Flexible and Economic Production

Vacuum casting or urethane casting is a technology that combines silicone molds and a 3D printed master pattern to create short-run, rigid parts with production-level quality. The process hardens thermoplastic polyurethane inside silicon or epoxy molds. The result is vacuum casting parts with the same shapes as the original master models. The final dimensions of the vacuum casting parts will depend on the master model, part geometry, and the material chosen.

As a leading vacuum casting manufacturer, cncjsd offers low-cost fabrication of high-quality plastic parts. This technology eliminates the need for expensive upfront investments. Our vacuum casting services offer the complete solution for creating excellent quality prototypes and low-volume production parts.

Why Vacuum Casting

Unmatched Lead Time

We combine our extensive technical experiences and advanced technologies to deliver superior urethane casting services with faster lead times.

Complex Geometries Support

We use high-quality elastomeric materials to ensure the manufacture of vacuum casting plastic parts with complex structures. Offer detailed design support to ensure your prototypes and small-batch components are closely similar to the intended final products.

Flexible Color Options

We carefully incorporate various color pigments to achieve the intended effects on your finished products. You can select from our extensive list of color options.

Material and Finishing Selection

Choose from a wide range of possible materials and surface finishes for your vacuum cast parts. We provide the highest quality resins to ensure superior product quality, and offer a wide range of surface finishing options to bring your product to life.

Flexible Color Options

cncjsd is proudly ISO certified, ensuring our products and services comply with international quality standards. We offer manufacturing analysis and quality control to provide parts that meet the highest standards.

Professional Vacuum Casting Specialists

Get reliable custom vacuum casting services from highly skilled and experienced specialists. We boast the best hands in the industry with expertise in fabrication, material selection, surface finishing, and many more.

Vacuum Casting from Prototyping to Production

Vacuum casting is the ideal solution for creating high-quality prototypes and small-batch parts for different applications. We help you reach your manufacturing goals.

Prototyping

The vacuum casting process involves low-cost tooling to ensure a more accessible and cost-effective way of creating prototypes. Create quality prototypes with various materials and design changes. Test your designs easily and get them ready for functional testing.

Market Testing

We help you create vacuum casting products ideal for market and consumer testing, concept models, and user evaluation. These parts come with high-quality finishes and end-use functionalities. Our urethane casting services allow you to incorporate changes quickly for further testing and market launch.

On-Demand Production

Vacuum cast parts are excellent options for custom and first-run production. You can cost-effectively test product quality before starting full-scale production.

Vacuum Casting Tolerances

cncjsd offers a range of vacuum casting tolerances to meet your custom requirements. Based on the master pattern and part geometry, we can reach dimensional tolerances between 0.2 – 0.4 m. Below are the technical specifications for our vacuum casting services.

| Type | Information |

| Accuracy |

Highest precision to reach ±0.05 mm |

|

Max Part Size |

+/- 0.025 mm+/- 0.001 inch |

|

Minimum wall thickness

|

1.5mm~2.5mm |

|

Quantities |

20-25 copies per mold |

|

Color & Finishing |

Color and texture can be customized |

|

Typical Lead Time |

Up to 20 parts in 15 days or less |

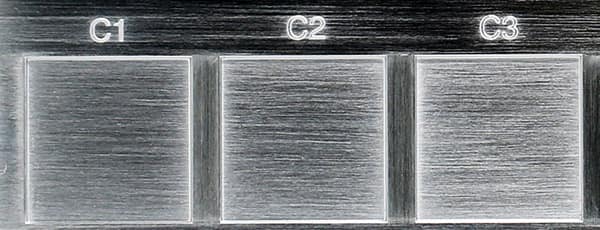

Surface Finish for Vacuum Casted Parts

With an extensive array of surface finishes, cncjsd can create unique surface layers for your vacuum casting parts. These finishes help you meet your products’ appearance, hardness, and chemical resistance requirements. Depending on your material selection and part applications, we can offer the following surface finishes:

Gallery of Vacuum Casting Parts

We have been helping various industries such as aerospace, automotive, medical devices and other industries to develop various elastomeric vacuum cast parts since 2009.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

We have benefited greatly from cncjsd urethane casting capabilities. Our company needed pre-launch prototypes for first-run functional testing, and they recommended urethane casting as the ideal option. We got high-quality castings that met every one of our specifications. Our customers have expressed satisfaction in terms of usage of these components.

I wholeheartedly recommend cncjsd vacuum casting services for any company looking to produce precise castings. Over the past 6 years, I have examined a lot of casting tools made by different companies and concluded that cncjsd offered incredible value. When you consider the machine’s cost, quality, and output, I’m confident you won’t find a better casting service for your money.

Our company handles a lot of complex cases. Since we started using cncjsd, the castings’ consistency, quality, and cleanliness have all significantly improved. Their quick response, manufacturing efficiency, and fast delivery saves us a lot of time.

Our Vacuum Casting Service for Various Industrial Applications

Due to its fast production, low costs, and durable parts, our vacuum casting service is the favored option for making custom parts used in the automotive, medical, consumer goods, and other industries.

Vacuum Casting Materials

You can choose a wide range of vacuum casting materials depending on the peculiarities of your project. These resins are typically analogs of common plastic materials with comparable performance and appearance. We have grouped our urethane casting materials into general categories to help you make the best decisions for your project.

ABS-Like

Versatile polyurethane plastic resin that is analogous to ABS thermoplastic. Hard, rigid, and impact resistant, it is ideal for various products.

Price: $$

Colors: All colors; precise pantone color matching available

Hardness: Shore D 78-82

Applications: General purpose items, enclosures

Acrylic-Like

Stiff, transparent urethane resin simulating acrylic. It is hard, with medium to high strength and good clarity for see-through products.

Price: $$

Colors: Clear

Hardness: Shore D 87

Applications: Light pipes, see-through components

Polypropylene-Like

Tough, flexible, and abrasion-resistant urethane with low cost and polypropylene-like ductility.

Price: $$

Colors: Black or natural only

Hardness: Shore D 65-75

Applications: Enclosures, food containers, medical applications, toys

Polycarbonate-Like

Tough, flexible, and abrasion-resistant urethane with low cost and polypropylene-like ductility.

Price: $$

Colors: Black or natural only

Hardness: Shore D 65-75

Applications: Enclosures, food containers, medical applications, toys

PMMA

UV stable, high-quality urethane resin with good clarity. Great for glossy, clear parts as a classic substitute for acrylic-like.

Price: $$

Colors: RAL/Pantone colors

Hardness: Shore D 90-99

Applications: Lighting, signal display, partition material

PS

High impact strength, low-cost resin with a wide range of options.

Price: $$

Colors: Pantone colors

Hardness: Shore D 85-90

Applications: Displays, disposable items, packaging

Elastomer

Polyurethane plastic resin, simulating rubber-like materials like TPU, TPE and silicone rubber.

Price: $$

Colors: All colors and precise Pantone color matchings

Hardness: Shore A 20 to 90

Applications: Wearables, overmolds, gaskets

Quality Parts Made Easier, Faster