24H

Qoso e matla

Matsatsi a 10

Lead time

0PC

Moq

0.010 mm

Ho mamella

Litšebeletso tsa rona li ka etsahala

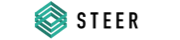

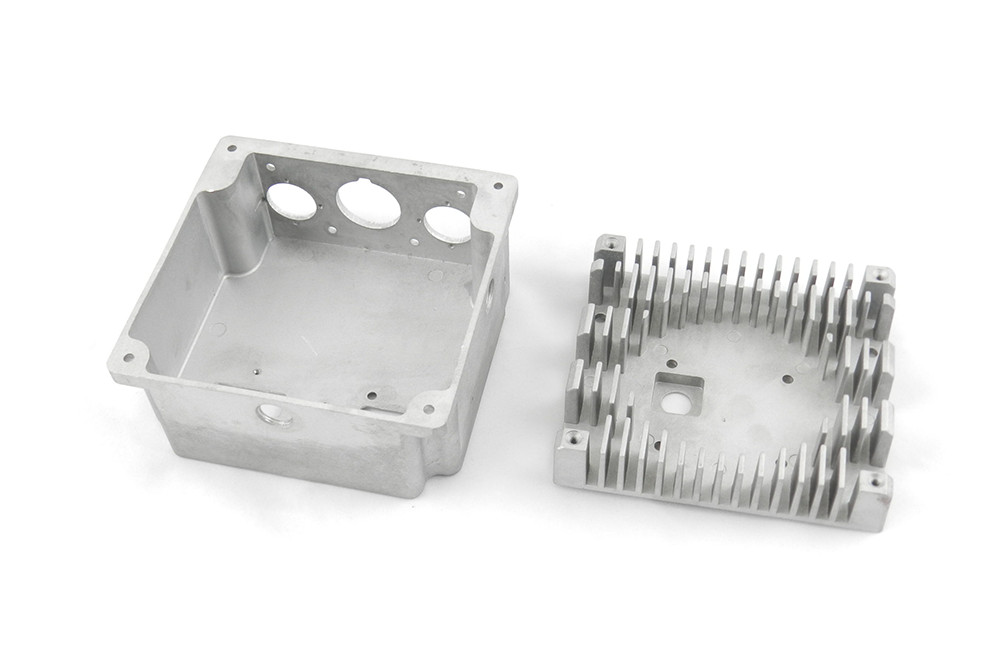

Haeba u na le litlhoko tsa likarolo tsa tšepe tsa moetlo, cncjsd ke moetsi oa litšebeletso tsa litšebeletso tse bolaeang tse ka thusang. Ho tloha ka 2009, re tšoare sehlopha sa rona sa boenjiniere le lisebelisoa ho maemo a phahameng ho tsamaisa likarolo tse matla le tse tšoarellang. Ho etsa bonnete ba boleng bo phahameng, re sebetsa ka thata ts'ebetso ea ho lahla lintho ka thata tse netefatsang hore litlhoko tsa hau tsa tloaelo li khotsofatsoa. Tsena ke mefuta e 'meli ea bokhoni ba ho bolaoa.

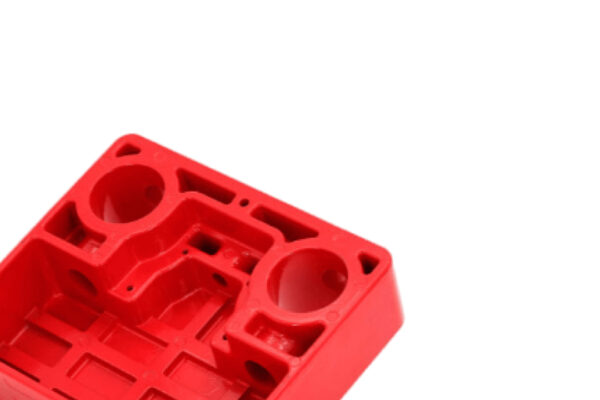

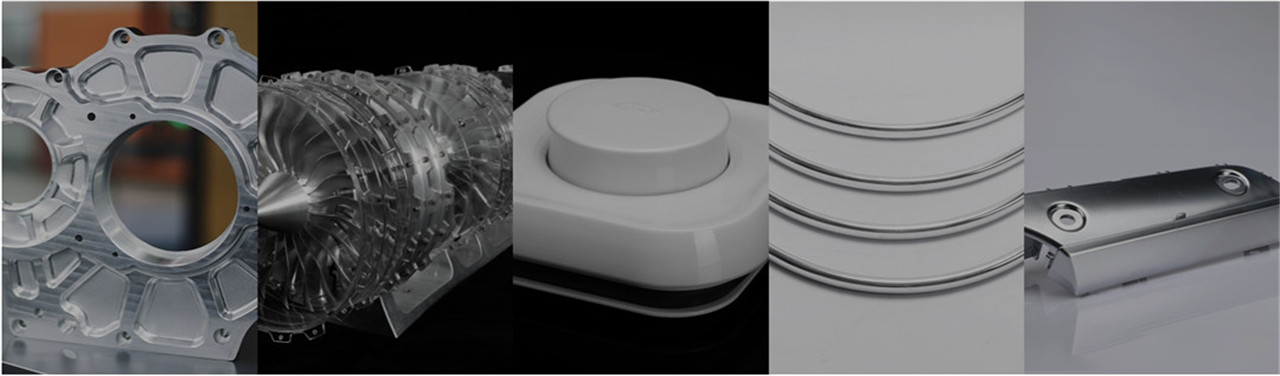

Kamore ea ho chesa ho chesa

Kamore e chesang e bola, e tsejoa hape e le gooseneck e potlakileng ka potoloho e potlakileng ea ho lahla metsotso e 15 ho isa ho e 20 ho isa ho e 20 ho isa ho tse 20. E lumella tlhahiso e phahameng ea ho ntlafatsa likarolo tse rarahaneng.

Ts'ebetso ena e loketse Zinc Holoy, Lean Alloys, koporo le likhahla tse ling tse nang le ntlha e qhibilihang.

Ho bata ho bata

Ke mokhoa oa ho batang oa kamore ea ho lahla lintho tse batang ke ts'ebetso ea bohlokoa haholo e thusang ho fokotsa palo le ho rarolla bothata ba lijalo le ho amana le likarolo tse amanang le mochini.

Ts'ebetso e sebelisoa haholo bakeng sa lintlha tse phahameng ka lintlha tse qhibilihang, joalo ka aluminium, magnesium, koporo e itseng le mahlaseli a itseng.

Hobaneng u khetha pefo ea likarolo tsa ho lahla lintho

Likhetho tse ngata

Re fana ka mefuta e fapaneng ea mefuta-palo ea lisebelisoa, bokaholimo ba ho mamella, ho mamella le lits'ebetso tsa thepa bakeng sa likarolo tsa hau tsa ho lahla. Ho latela litlhoko tsa hau tsa tloaelo, re u fa linyeoe tse fapaneng le litlhahiso tse ling e le hore u ka fumana mokhoa o le mong le tharollo e sebetsang ka ho fetisisa.

Semela se matla le lits'ebeletso

Re thehile lijalo tsa rona Chaena ho etsa bonnete ba hore likarolo tsa hau tsa ho lahla li entsoe ka katleho le nako e potlakileng ea ho phela. Ntle le moo, bokhoni ba rona ba ho etsa ha rona ba nka monyetla ka bokhoni ba merero ea hau ea ho lahla lintho tse entsoeng hara shoa, leha merero ea bona e thata.

Taolo ea boleng bo holimo

Re ISO 9001: Khamphani e Setifikeiti ea Setifikeiti sa 2015 le ho ikemisetsa ho fana ka litšebeletso tsa ho lahla lintho tsa ho lahla lintho. Sehlopha sa boenjiniere se ne se inehetseng sa boenjiniere sa Ccnjs se se tiisa tlhahlobo ea boleng bo boima ka mekhahlelo e fapaneng ea ts'ebetso ea tlhahiso le pele ho ne ho etsa hore likarolo tse phahameng tsa boleng li etselitsoe.

Sethala sa Marang-rang sa Marang-rang

Sethala se tsoetseng pele se qotsa sethaleng sa marang-rang ho u thusa ho kenya lifaele tsa meralo 'me u qoelisoa ka lebelo bakeng sa likarolo tsa tšepe tsa hau tsa tšepe nako eohle le kae kapa kae. Ts'ebetso ea ho lelekisa sethala sa rona sethaleng sa rona e u lumella ho lekola litaelo tsohle tsa hau le mantsoe a qotsitsoeng 'me u shebelletse mohato ka mong oa ts'ebetso ea tlhahiso hang-hang u beha litaelo. Sena se etsa hore ts'ebetso ea odara e hlahe ebile e hlakile.

Dead ho lahla ho tloha moo ho faneng ka ho etsa tlhahiso

Tloaetso ea shoa ke mokhoa o sebetsang oa ho hlahisa li-prototypes tsa boleng le likarolo tse nyane, o e khetholla likopo tse ngata. Sehlopha sa rona se mona ho u thusa ho fihlela sepheo sa hau sa tlhahiso ka ho fana ka litšebeletso tsa ho lahla liithuti tsa ho lahla liithuti.

E fafatsa

Le mokhoa o theko e phahameng le o sebetsang oa ho theha li-itotype tsa boleng bo holimo. Ts'ebetso ena e sebelisa lisebelisoa tse theko e tlaase, li e etsa tsela e leka-lekaneng ea ho hlahisa li-proteypes tse nang le lisebelisoa tse fapaneng le liphetoho tsa moralo.

Tlhahlobo ea mmaraka

Re u thusa ho etsa lihlahisoa tsa lihlahisoa tse lahlehileng tse loketseng bakeng sa tlhahlobo le tlhahlobo ea tumello, mehlala ea mohopolo le tlhahlobo ea mosebelisi. Litšebeletso tsa rona tsa Deewing tsa Die tsa Dieting li u lumella ho kenyelletsa liphetoho kapele bakeng sa teko le mabenkele.

Tlhahiso ea tlhoko

Lintjello tsa Cash ke likhetho tse ntle bakeng sa tlhahiso ea moetlo le ea pele. U ka leka litšenyehelo tsa sehlahisoa pele u qala tlhahiso e felletseng.

Tloaelo ea ho lahla melao ea mahlale

| Bophahamo | Litekanyetso |

| Boima ba karolo ea bonyane | 0.017 kg |

| Boholo ba boima ba 'mele | 12 kg |

| Boholo ba karolo ea karolo | ∅ 17 mm × 4 mm |

| Boholo ba karolo ea boholo | 300 mm × 650 mm |

| Bonyane bo boholo ba lebota | 0.8 mm |

| Bofani bo boholo ba lebota | 12.7 mm |

| Sehlopha sa Toleration bakeng sa ho lahla | Iso 8062 St5 |

| Bonyane batch e ka khonehang | 1000 li-PC |

Li-Deeps tsa ho lahla

Ho sebetsa ka poso le ho qeta ke mohato oa ho qetela oa ho nepahala ho shoa. Ho qeta ho ka kenngoa ho tlosa likokoana-hloko tsa likarolo tsa leleka, matlafatsa thepa ea lik'hemik'hale kapa ea lik'hemik'hale le ho ntlafatsa sebopeho sa litlolo. Ho na le mefuta e tšeletseng ea likhetho tsa ho qeta nako e telele.

Lits'ebetso tsa ho lahla likopo

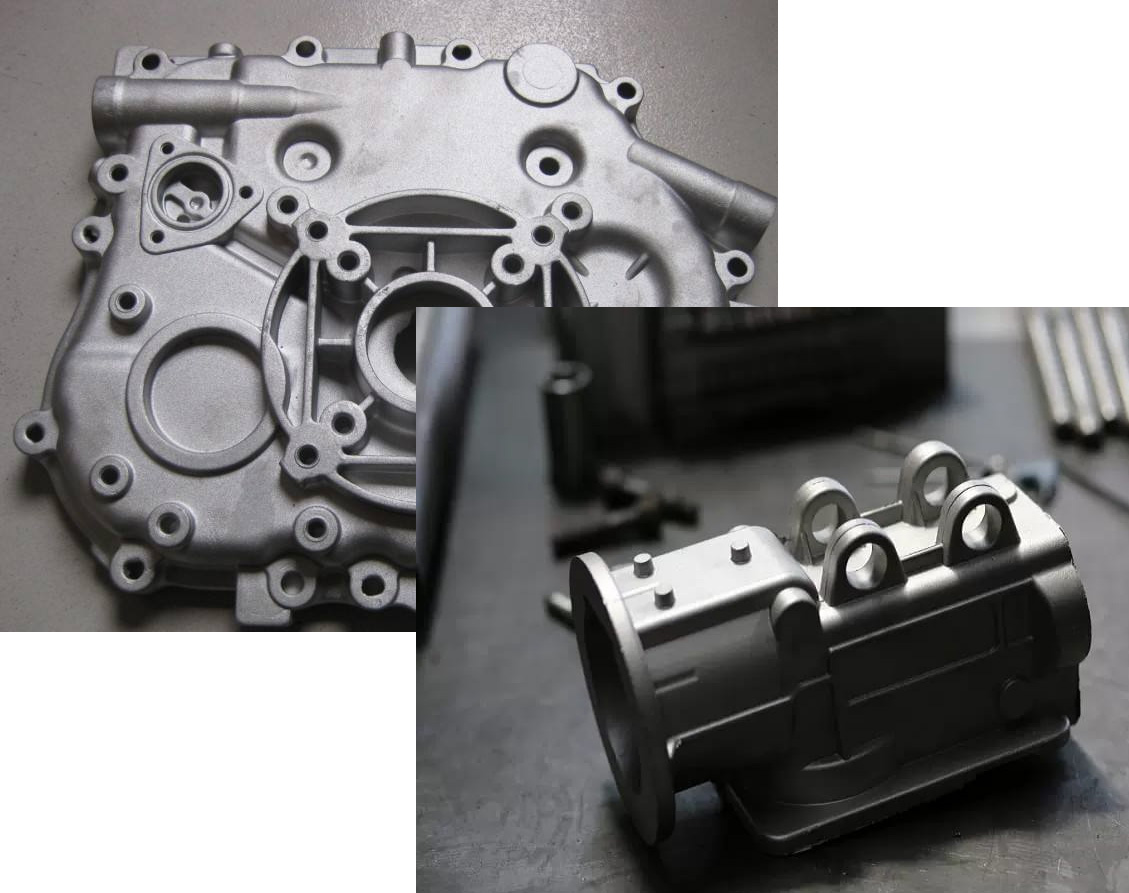

Ho lahla mekhoa ke mokhoa o sa fetoheng oa tlhahiso, 'me e phetha karolo ea bohlokoa ho theha le ho hlahisa lihlahisoa tse ngata tsa sebopeho sa Aerospace. Ccncjsd o fane ka tharollo ea tlhahiso ea lihlahisoa tsa boiphetetso ba indasteri e fapaneng. Re fana ka likarolo tsa boleng ba boleng ba litheko tsa tlholisano ho lefella bareki ba indastering e latelang:

Likarolo tsa likoloi tsa likoloi: Joalo ka ha li-disit tsa li-diast tsa li-dialet tsa li-diast, re tloaela ho etsa likarolo tsa koloi joaloka lefapha, likarolo tse nyane tsa enjine, esita le likarolo tsa mohloa.

Indasteri ea Aerospace: Khatello ea Magnesiunes

Likarolo tsa mabone: Tšebeletso ea rona ea ho lahla lintho le eona e ea ho ts'oaroa ha motlakase, e bola ea mocheso, 'me likarolo tse ngata tse tlosoang.

Lihlahisoa tsa khoebo le bareki re boetse re etsa likarolo tsa khoebo tse kenyelletsang li-costons le lithupa, matloana a siling e ngata.

Sebaka sa pokello ea libaka tsa ho lahla lintho

Hlahloba partory ea rona e mengata e bonts'ang ho hlaka ho tloha ho bareki ba rona ba bohlokoa.

Bona seo bareki ba rona ba se buang ka rona

Mantsoe a moreki a na le tšusumetso e kholo ho feta likopo tsa k'hamphani - 'me u bone hore na bareki ba rona ba khotso ba khotsofetseng ba boleletse eng mabapi le hore na re phethahatsa lintho tseo ba li hlokang joang.

Ke sebelisitse lits'ebeletso tsa ho lahla lintho tsa ccncjsD ho tloha ka June 2019. Li lula li arajoa, 'me li lula li arajoa,' me li setsebi ha se arabela likopo tsa ka. Cncjsd o ntse a thusa ho hlahisa meralo ea ka ea nnete, 'me karolo e' ngoe le e 'ngoe e feta litebello tsa ka.

K'hamphani ea rona e laetse hore aluminium e shoa likatse tseo re li hlokang bakeng sa ts'ebetso ea kopano e tsoang Cronjsd. Re na le litlhoko tse nepahetseng haholo tsa tlhahiso, tseo cncjsd li khona ho kopana. Li fana ka thepa ea boleng bo holimo ka theko e loketseng. Re tla lula re sebelisa CncJSD, 'me re eletsa k'hamphani efe kapa efe e hlokang ho etsa joalo!

Ikopanye le Cncjsd bakeng sa efe kapa efe ea litlhoko tsa hau tsa aluminium ea ho lahla. Re sebelisa mola oa bona oa tlhahiso bakeng sa likarolo tsa koloi. Li tiisa bophelo bo le bong ba bareki ba rona. Ts'ebeletso ea bona ea bareki e ne e le bonolo ho e fihlela, 'me ha re kopane le mathata ebile e tla lula re tšehetsana le ho bua.

Cnc ea rona ea CNC ea Recidation ea Liindasteri tsa indasteri

Cncjsd o sebetsa le baetsi ba etellang pele ho indastering e fapaneng ho ts'ehetsa litlhokahalo tsa bona tse holang. Ho sebelisa likolo tsa rona tsa cnc mechini ea mofuta oa cnc ho thusa bahlahisi ba eketsehileng ho thusa bahlahisi ba eketsehileng ho tlisa mohopolo oa bona ho lihlahisoa.

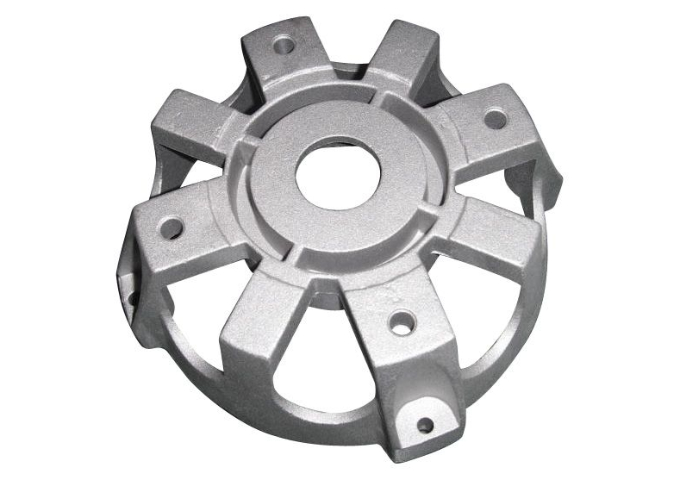

Aloys o ne a tloaetse ho etsa likarolo tsa ho qhalana

Mefuta e seng-morao e nang le mocheso o tlase oa ho lahla lintho tse bolaeang, e ka sebelisoa joalo ka aluminium, Zinc, magnesiu, lead, koporo. Empa litšepe tse ling tse sa tloaelehang ebile tse belang li ka etsahala. Ba latelang ba tla hlalosa thepa ea ba sebelisang li-soloys tseo re li sebelisang bakeng sa likarolo tse ngata.

Aluminium Alloys

Aluminium Diding Alloy ke Metal e bobebe haholo-holo e nang le silinon, koporo, tšepe, manganese le zinc.

E bonts'a pherekano e phahameng ea motlakase, boitšoaro ba motlakase, ba ho fokolisa ts'ebetso, le shrinkage e nyane, e etsa hore e be le ts'ebetso e ntle haholo le ho tlatsa.

Ho feta moo, lifofane tsa Aluminium li ka boloka thepa e ntle ea mecha ea ka tlasa mocheso o phahameng kapa o tlase ka lebaka la letsoalo le lenyane le matla a phahameng.

Tloaelehileng alominum e sebelisitsoeng alominum:

A380, A360, A390. A413, ADC-12, ADC-1

Zinc Alloys

Lintho tse ka sehloohong tse kenyellelitsoeng ho Zinc Diling allow e lahlehileng, koporo le magnesium.

E fana ka pheletso e ntle ntle le tlhoko ea ts'ebetso ea bobeli. Habone, Zinc Alloy o theko e boima ebile e matla ho feta tse ling tse ratoang.

Hape, ho na le ho itšilafatsa hantle le ho ikarola ka bongata ho joalo ka li-metress tse lahleloang, hosie ea likoloi le likarolo tse ling tse thata tsa tšepe.

E tloaetse ho sebelisa li-zinc tse tloaelehileng:

Zamak-2, Zamak-3, Zamak-5, Zamak-7, Za-8, Za-12, Za-12, Za-27, Za-27, Za-27, Za-27, Za-27, Za-12, Za-27

Magneium aloys

Lintlha tse ka sehloohong tsa Magnesiumy Dialting Alloy, Tenanese, Mardium, Thorium, Zadmoum kapa Cadmium.

E na le melemo ea matla a mangata, lipampiko tse tlase, ho ikhatholla botle le ho tlatsa maemo a matle a ho tlatsa melao e thata.

Magnesium Lello e ka sebelisoa bakeng sa ho lahla hlobo le likarolo tse tšesaane tse tšesaane ntle le mapetso a futhumetseng.

Tloaelehileng magnesiumy aloys:

AZ91D, AM60b, AS41B

Likarolo tsa boleng ba boleng bo botle, kapele