CNC (Computer Numerical Control) production technology plays an important role in modern manufacturing, and its efficient and precise processing methods have brought huge changes to many industries. However, like any manufacturing process, there is a cost factor involved with CNC fabrication. This article will introduce the main aspects of CNC fabrication costs to better understand its economics and challenges.

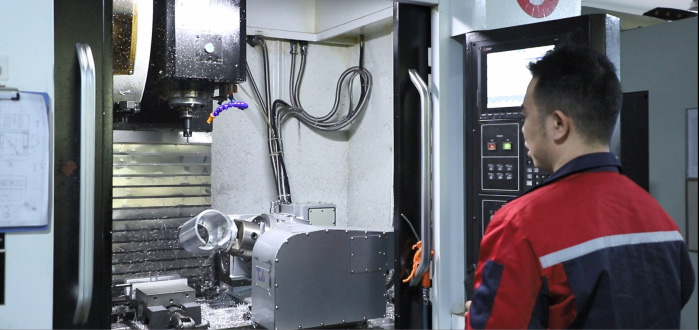

First of all, the cost of CNC production is affected by equipment and tools. CNC machine tools are the core equipment for automated processing, and their prices are often expensive. Different types and sizes of CNC machine tools have different price ranges, ranging from small machines to large, complex multi-axis machines, and their prices can vary widely. In addition, other ancillary equipment and tools need to be considered, such as cutters, jigs and measuring instruments, which also add to the cost of production.

Secondly, the cost of CNC production is also related to material selection. Different materials have different characteristics and difficulties. For CNC processing, some materials may require more wear-resistant tools, more complex processing paths, or stricter process requirements, which will increase costs. High-performance alloys, composites, and specialty materials are generally more expensive, while metallic materials (such as aluminum, steel, copper, etc.) are relatively common and economical.

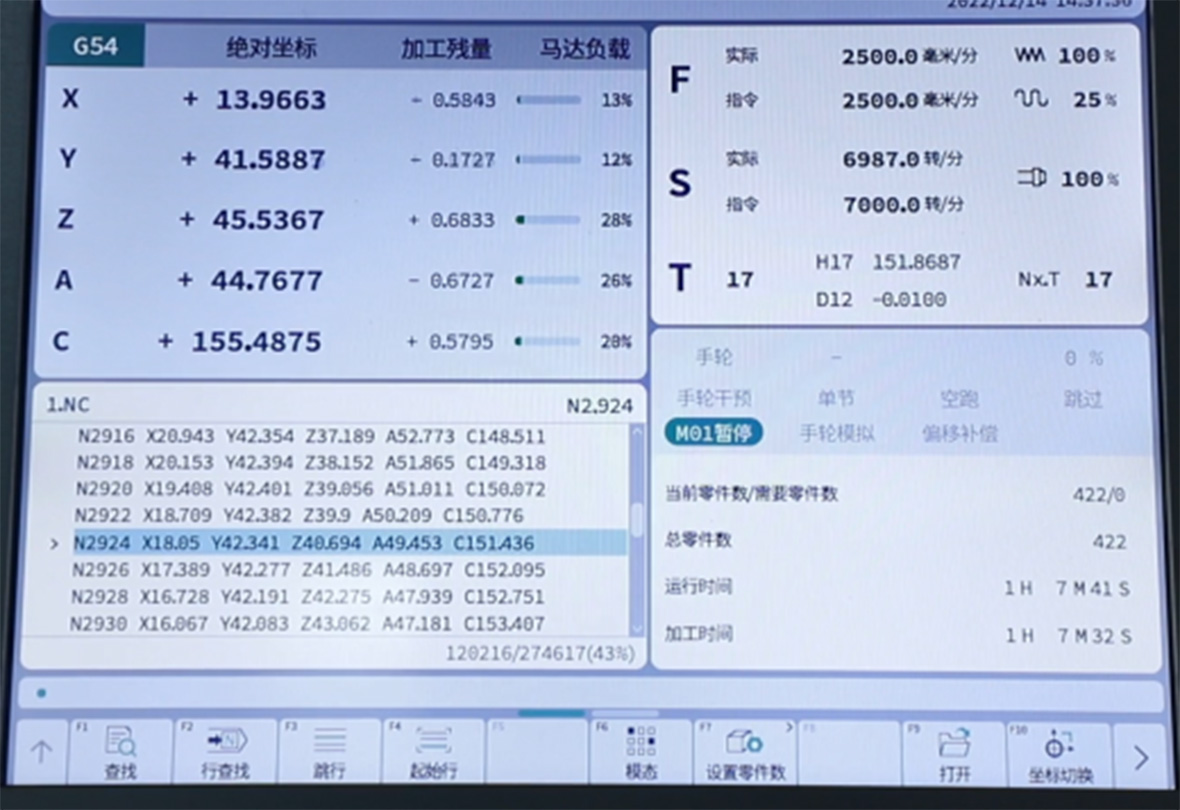

Third, programming and design are also important cost factors in CNC production. In CNC production, writing G code or CAM files suitable for machine tools is essential. This requires technicians with professional knowledge and experience in product design and processing path determination in drawing software and programming software. The complexity of programming and design depends on the complexity and requirements of the product, so more complex products often mean higher programming and design costs.

In addition, CNC production also involves equipment maintenance and operating costs. The stability and accuracy of machine tools require regular maintenance and upkeep to ensure their normal operation and accurate processing. Operating costs include aspects such as energy consumption, tool replacement and transportation, and these costs depend on the size and complexity of the process.

It should be noted that although CNC production may involve higher initial investment and running costs, its accuracy, efficiency and repeatability can often bring better economic returns. Through automation and precise processing, CNC production can reduce manual operations and reduce human errors, thereby improving production efficiency and product quality.

In short, CNC production involves many cost factors. Equipment and tools, material selection, programming and design, maintenance and operation are the main factors that affect the cost of CNC manufacturing. Understanding these factors can help better evaluate the economics and feasibility of CNC fabrication and make informed decisions for manufacturers and businesses. With the continuous advancement of technology and competition in the market, we can expect that CNC production costs will be further optimized and reduced to better meet a wide range of manufacturing needs.

Post time: Oct-23-2023