30T-1800T

Moulding Tshuab

12

Nto tas

0pc

Moq

0.05mm

Kev thev

Peb Txhaj Tshuaj Moulding Peev

Los ntawm cov qauv yas tiv thaiv yas rau ntau lawm molding, CNCJSD Custom Kev Tsim Kho Tshuaj Molding yog qhov zoo rau kev tsim khoom ntawm cov nqi sib tw hauv lub sijhawm nrawm. Cov khoom tsim muaj zog nrog cov khoom siv muaj zog, meej meej tib yam nkaus pwm cov cuab yeej rau tsim cov khoom sib xws. Zoo dua, peb muab cov kws tshaj lij dawb sab laj ntawm txhua qhov kev txhaj tshuaj pwm, suav nrog cov lus qhia pwm, suav nrog kev xaiv pwm, suav nrog kev siv cov ntawv thov siv, thiab cov hau kev thauj khoom.

Yas Txhaj Pwm

Nrog peb cov kev paub thiab siab tshaj plaws machinery, peb muaj txiaj ntsig ntawm kev tsim qauv thiab tsim cov yas txhaj tshuaj pwm kho rau koj tus nqi kho thiab raug nqi.

Yas Txhaj Moulding

Peb cov yas txhaj tshuaj moulding kev siv cov tshuab tua kom zoo nkauj rau hauv cov pwm ua kom muaj cov pwm kawg-qib kawg-qib.

Dhau

Hau yas, hlau, thiab cov roj hmab hla txhua lwm ntawm kev sib koom tes rau kev sib tw, peb ntau dua kev sib dhos ua ke thiab muab cov khoom siv ntau dua.

Nthaw Moulding

Ntxig moulding yog cov txheej txheem ntawm molding cov khoom siv thermoplastic nyob ib ncig ntawm ib qho kev xaiv ua ke los tsim ib feem ua tiav uas cuam tshuam ntau cov ntaub ntawv.

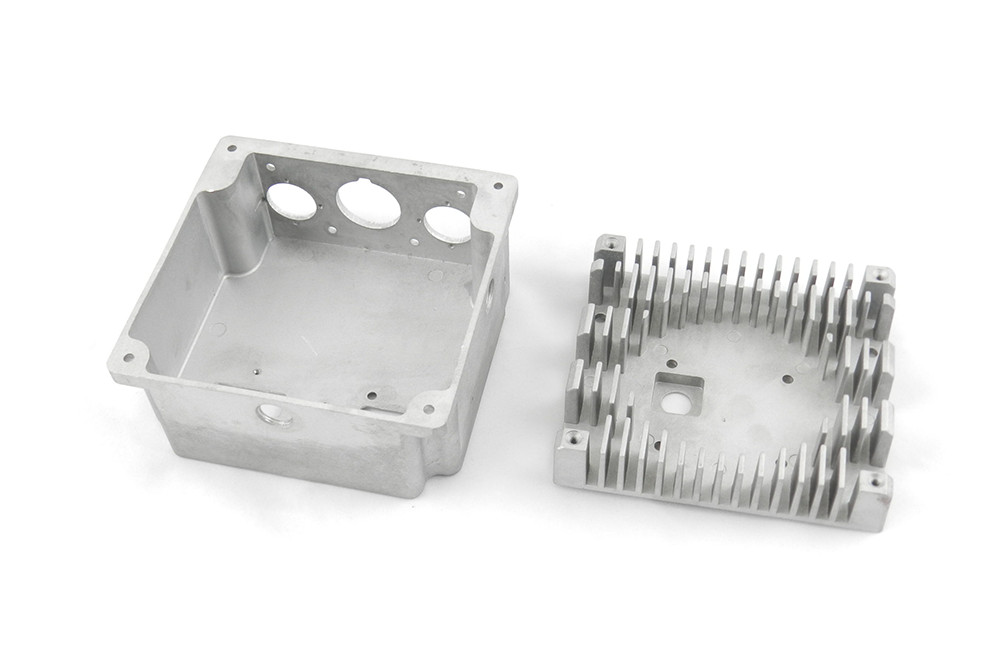

Tuag Casting Los Ntawm Prototyping Rau Ntau Lawm

Saib seb peb ua koj cov xaj li cas, los ntawm cov lus hais los ntawm kev txua, raws li peb cov tshuab thiab cov pab pawg ua tau zoo kom koj tau txais koj cov pwm thiab cov khoom siv hauv lub sijhawm teem tseg.

Thov rau nqe lus

Thov koj cov lus los ntawm peb cov enterication (peb cov enversation online thiab peb cov enversal engine

Daim ntawv qhia DFM

Txhawm rau kom peb tuaj yeem tsim cov pwm ua haujlwm, peb tau ua kom pom kev ua haujlwm ntawm koj tus qauv tsim kom peb tuaj yeem ua tiav cov kev yuav tsum ua ntej pib tsim khoom.

Kev Tshawb Xyuas Pwm

Kev twv ua qauv software pab peb saib cov khoom siv molten tsiv thiab ua hauv pwm, uas pab peb xa kev txhim kho.

Pwm Cuab Yeej Siv Ntau Lawm

Pib kev tsim cov tshuaj pleev raws li koj cov ntawv thov tshwj xeeb xav tau los ntawm kev siv cov ntaub ntawv thiab ua tiav ntawm koj xaiv.

T1 Cov Qauv Qhia Txog T1

T1 piv txwv yuav xa rau koj los tshuaj xyuas cov khoom yas tsim khoom kom paub tseeb thiab ua tau zoo.

Tsawg Voos Ntau Lawm

Tom qab ua tiav cov theem kev sim ntau lawm, peb pib mus rau cov tshuab tshuab siab dua, siv cov tshuab siab dua los tsim cov khoom kom nrawm thiab muaj txiaj ntsig.

Kev kuaj nruj

Cov txheej txheem tshuaj xyuas kev nruj, suav nrog kev tshuaj xyuas kev ua haujlwm, qhov loj me, thiab qhov tsos, kom paub tseeb tias cov ntu uas yuav tsum tau ua tiav.

Kev xa mus

Tom qab kev soj ntsuam kom huv si, peb yuav xa koj cov khoom rau koj sai li sai tau thaum ua kom lawv muaj kev nyab xeeb.

Txhaj tshuaj molding los ntawm protyping rau ntau lawm

Tuag casting yog ib txoj kev ua tau zoo rau kev tsim cov qauv zoo nkauj saum toj kawg nkaus thiab cov khoom me me, ua rau muaj kev xaiv zoo heev rau ntau cov ntawv thov. Peb pab neeg nyob ntawm no los pab koj hauv kev ua tiav koj lub hom phiaj tsim khoom los ntawm kev muab cov kws tshaj lij tuag Casting kev pab.

Kev Too Sai

Tau yooj yim cov lus qhia yooj yim thiab siv tau los ntawm kev ua lag luam zoo dua qub. Tsim cov khoom me me ntawm cov yas pwm nrog kev txhaj tshuaj zoo moulding. Peb ua kom zoo ntawm kev tsim cov qauv pwm tawm hauv cov hnub los xyuas kom koj ua cov kev ntsuam xyuas ua haujlwm thiab siv tau cov kev nyiam ua lag luam.

Ntau Lawm Tooling

Peb tsim cov khoom siv zoo ntau lawm rau cov khoom ntim high-ntim ntau lawm. Nrog High-zog, lub cuab yeej siv hluav taws xob steel, peb cov cuab yeej tsim khoom yog tsim nyog rau kev tsim ntau pua txhiab feem. Peb tuaj yeem sib txawv cov ntaub ntawv thiab cov qauv tsim qauv raws li koj cov cai tshwj xeeb.

Kev txhaj tshuaj Molding Paus taus

| Tus qauv | Kev piav txog |

| Qhov siab tshaj plaws | 1200 × 1000 × 500 hli47.2 × 39.4 × 19.7 hauv. |

| Yam tsawg kawg nkaus ib feem loj | 1 × 1 × 1 hli0.039 × 0.039 × 0.039 hauv. |

| Ib feem rau qhov kev ua kom muaj | +/- 0.1 hli+/- 0.0039 Hauv. |

| Pwm Txoov Hlab Kev Pab Khwv | +/- 0.05 hli+/- 0.002 hauv. |

| Muaj cov hom pwm | Hlau thiab Aluminium Tooring. Cov Qeb Khoom Siv Ntau Lawm Peb muab: hauv qab 1000 ncig mus, hauv qab 5000 lub voj voog, thiab ntau dua 100,000 Cycles |

| Machine muaj | Ib Leeg kab noj hniav, ntau-kab noj hniav, thiab tsev neeg cov pwm,50 rau 500 nias tonnage |

| Cov haujlwm thib ob | Pwm texturing, ncoo luam ntawv, laser engraving, xov cov ntxig thiab sib dhos ua ke. |

| Kev kuaj thiab cov ntawv xaiv pov thawj | Thawj tshooj xov xwm, ISO 9001, ISO 13485 |

| Lem sij hawm | 15 hnub ua haujlwm lossis tsawg dua rau cov kev txiav txim siab tshaj plaws,24/7 Lus teb |

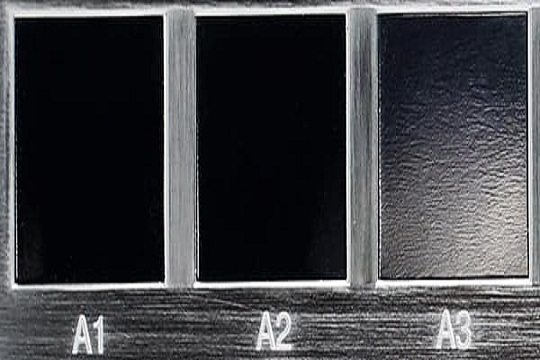

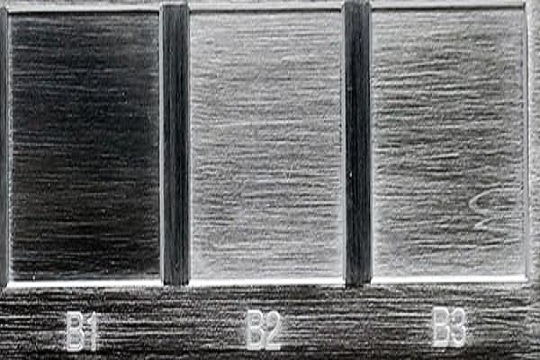

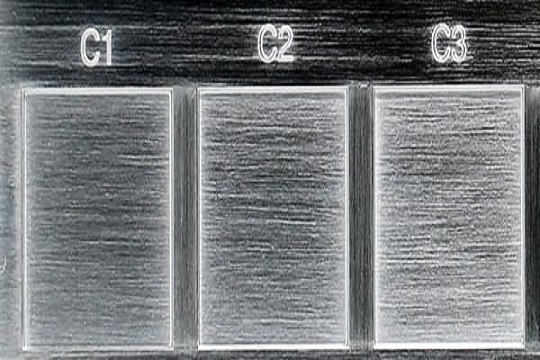

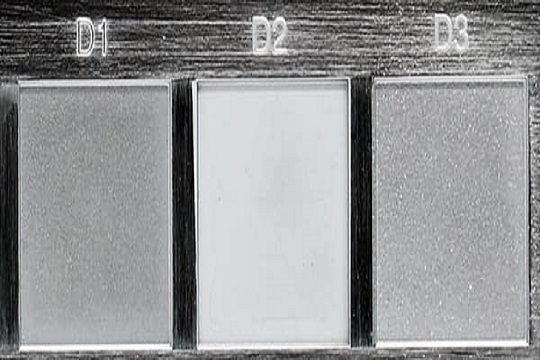

Chav Kawm Kev Txhaj Tshuaj Molding Pwm

Ntawm cncjsd, peb tsim thiab tsim kho cov kev txhaj tshuaj tshwj xeeb los ntawm cov ntaub ntawv zoo. Peb cov txheej txheem ua kom muaj kev tsis sib xws tsis sib xws thiab kev rov ua dua ntawm cov sijhawm coj ua kom ceev thiab pheej yig. Txhua cov yas txhaj tshuaj molding peb ntaub npuag sib ntsib cov qauv thoob ntiaj teb. Los ntawm ib-tawm cov haujlwm mus rau me me batches thiab ntau lawm tooling, peb muab ruaj thiab txhim khu kev qha cov cuab yeej siv pwm.

| Pwm chav kawm | Lub hom phiaj | Tua lub neej | Kev nyiaj tau | Tus nqi | Lem sij hawm |

| Hoob 105 | Kev Ntsuas Cov Qauv Ntsuas | Nyob rau hauv 500 txog | ± 0.02mm | $ | 7-10 hnub |

| Hoob no 104 | Tsawg-ntim ntau lawm | Nyob rau hauv 100.000 mus | ± 0.02mm | $$$ | 10-15 hnub |

| Chav Kawm 103 | Tsawg-ntim ntau lawm | Nyob rau hauv 500.000 lub voj voog | ± 0.02mm | $$$$ | 10-15 hnub |

| Hoob 102 | Nruab Nrab-ntim Ntau Lawm | Nruab Nrab rau Kev Ntau Lawm | ± 0.02mm | $$$$$$ | 10-15 hnub |

| Hoob no yog 101 | High-Volum Ntau Lawm | Tshaj 1,000,000 mus | ± 0.02mm | $$$$$$$ | 10-18 hnub |

Nto tas los ntawm Kev Txhaj Tshuaj Molding

Kev txhaj tshuaj molding suav nrog kev txhaj tshuaj pwm, kev txhaj tshuaj yas, thiab lwm yam. Cov kev kho saum npoo av ntawm cov pwm feem ntau yog ua tiav thaum lub sijhawm tsim khoom. Tom qab txhaj tshuaj molding yog ua tiav, peb yuav ua qee cov kev kho mob saum npoo ntawm cov khoom tiav raws li qhov koj xav tau.

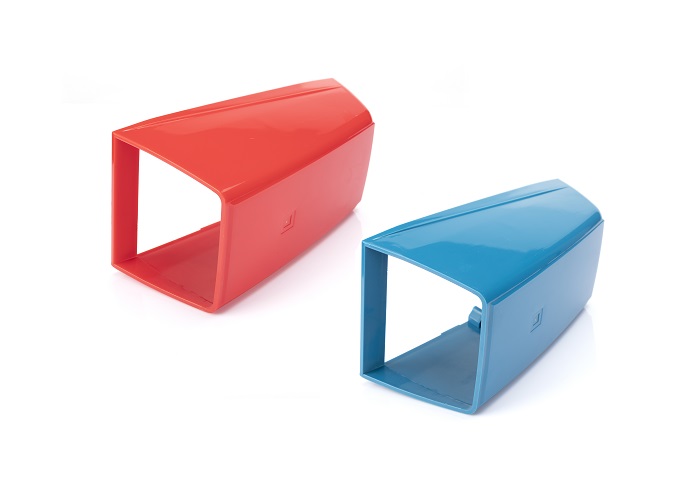

GALLERY ntawm txhaj Molding Qhov Chaw

Dhia rau hauv cov duab txuas ntxiv uas ua rau pom kev txhaj tshuaj uas peb tuaj yeem tsim koj cov kev txhaj tshuaj molding raws li koj cov kev nruj me ntsis.

Vim li cas thiaj xaiv Cncjsd rau kev txhaj tshuaj Kev Kho Mob

Tsis muaj moq

Txwv tsis pub txiav txim yam tsawg kawg nkaus uas yuav tsum pab txav cov khoom siv nrawm nrawm thiab txhawb koj cov kev tsim kho cov nqi sib xyaw.

Siab efficiency

Nrog lees paub cov chaw ua haujlwm hauv tsev thiab cov khoom siv tau muab tso rau nrawm dua ntawm koj cov tshuaj txhaj tshuaj tuaj yeem sai li sai tau.

Sib xws thiab siab zoo

Owing tau lees paub cov ntaub ntawv pov thawj, kev tshuaj xyuas cov txheej txheem thiab cov ntaub ntawv pov thawj ua haujlwm tom qab ntau lawm ntawm cov qauv ua tau zoo nrog cov duab siab.

Txhaj Tshuaj Pwm Tshwj Xeeb

Ua haujlwm nrog peb cov kws tshaj lij muaj 10+ xyoo ntawm kev txhaj tshuaj moulding kev lag luam, ua tiav tiav ib qho kev ua yeeb yam los ntawm kev tsim khoom.

Npaj kom tau txais koj cov kev txhaj tshuaj kev txhaj tshuaj molding cov lus?

Kawm dab tsi koj xav tau ua ntej thov rau cov lus rau koj txhaj tshuaj molding cov haujlwm ntawm cncjsd. Pab koj kom tau txais cov tshuaj zoo ua tau zoo, yooj yim.

Saib seb peb cov neeg muas zaub tau hais txog peb

Cov qhua tuaj noj mov cov lus muaj ntau yam kev cuam tshuam ntau dua li lub tuam txhab cov nyiaj pab - thiab saib dab tsi peb cov neeg yuav txaus siab tau hais txog yuav ua li cas txog lawv cov kev xav tau.

CNCJSD tau ua peb tus khub moulding ntawm 2 xyoos dhau 2 xyoos. Txij thaum ntawd los, CNCJSD tau ua ntu zus rau peb nrog sab saum toj-moulded seem. Ib qho ntxiv, CNCJSD tau txais kev pabcuam sib dhos rau ntau yam qauv ntawm peb me ntsis ntsia hlau ntsia kom txog thaum cov khoom tiav kawg. Kuv txaus siab los pom zoo rau cov ntsiav tshuaj rau ib tus neeg nrhiav rau cov khoom siv sab saum toj-tsis siv cov khoom.

Cov neeg ua haujlwm ntawm CNCJSD tau pab peb hloov peb lub tswv yim mus rau hauv qhov chaw tiav rau ntau xyoo tam sim no. Cov txheej txheem los ntawm kev xeeb tub mus tsim tau yog du, ua tsaug rau lawv txoj kev paub, kev txawj, thiab "tuaj yeem ua" tus cwj pwm. Nov yog ib qho ntawm peb cov kev ua lag luam ua lag luam tshaj plaws vim yog cncjsd tseem ceeb rau cov neeg siv khoom txaus siab.

CNCJSD tau muaj txhij ua ke ua pov thawj los ua ib qho kev txhaj tshuaj sab saum toj ntawm kev txhaj tshuaj molding rau peb lub tuam txhab. Lawv tau ua siab rau peb nrog lawv cov kev tshaj lij, kev ncaj ncees, thiab tus nqi tsim nyog. Peb tau ntiav celjsd los tsim cov pwm rau peb, kho thiab hloov cov khoom siv uas muaj cov pwm uas tau ua kom haum rau peb cov kev xav tau, thiab xa cov khoom uas ua raws li peb txoj kev nruj me nyuam.

Peb CNC Machining Rau Ntau Yam Kev Lag Luam

CNCJSD ua haujlwm nrog cov thawj coj ua lag luam los ntawm ntau hom kev lag luam los txhawb nqa kev loj hlob thiab hloov lawv cov khoom siv. Cov digitalization ntawm peb kev cai CNC Machining Services pab ntxiv thiab ntau cov neeg tsim khoom coj lawv lub tswv yim rau cov khoom lag luam.

Cov Khoom Siv Rau Kev Txhaj Tshuaj Molding

Cov no yog cov moulded plastics uas peb txhaj tshuaj molding muab rau. Tom qab paub cov ntsiab lus ntawm cov ntaub ntawv, cov qib kawm ib txwm muaj, cov khoom lag luam, xaiv cov kev txhaj tshuaj molding nyob ntawm koj daim ntawv thov yuav tsum tau ua.

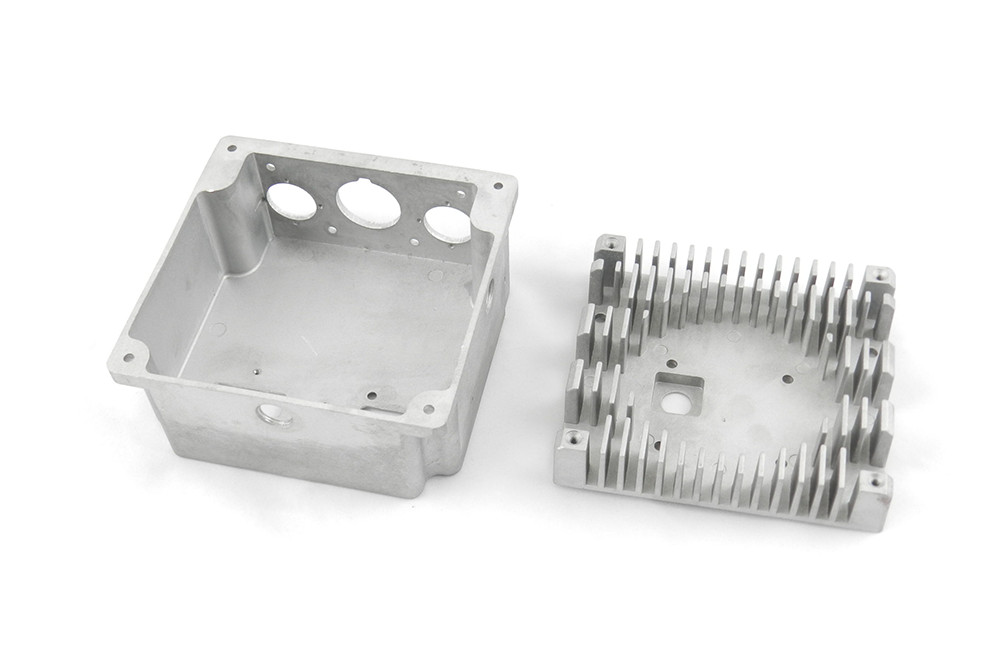

Cuab Yeej Tuam Txhab

Ua ntej txhaj tshuaj molding cov txheej txheem pib qis lossis ntau-ntim ntau lawm, lub siab tiv thaiv cnc machined tooling yog xav tau. Feem ntau cov ntaub ntawv siv tau suav nrog:

Cuab Steel: P20, H13, S7, S7, S7, S130, S136, S136H, 718, 718h, 738

Tus Hlau Stainless: 420, S136, 316L, 316, 301, 301, 304

Aluminium: 6061, 5052, 7075

Yas Khoom

Yas txhaj tshuaj molding cov kev pab cuam los nrog ntau cov ntaub ntawv nrog cov khoom sib txawv, suav nrog kev cuam tshuam lub zog, thermal kuj, tshuaj lom neeg, thiab lwm yam.

| Abs | Nylon (PA) | PC | Pvc |

| PU | PMMA | PP | Qab nkaub |

| PE | HDPE | PS | Pom |

Cov ntxiv thiab cov fibers

Cov qauv yas yuav tsis ntsib kev txhaj tshuaj kev txhaj tshuaj Molding Qhov uas yuav tsum tau. Hauv qhov no, cov quav ntxiv thiab cov fibers tuaj yeem muab ntxiv rau txhim kho kev ua kom zoo nkauj thiab cov khoom muaj nuj nqis, muab cov qauv ntxiv rau koj txhaj tshuaj molding.

| UV nqus | Cov xim |

| Nplaim taws retardants | Lub khob fibers |

| Yas tshuab |

Cov khoom zoo ua tau yooj yim dua, nrawm dua