24h

Nā hua'ōlelo RaidiD

10 mau lā

Ka manawa o waena o ka hoʻomaka a i ka wā pau

0pc

Moo

Paona 010 mm

Aiko

ʻO ko mākou hana e hana ana i nā lawelawe hana make

Inā loaʻa iāʻoe nā mea waiwai maʻamau,ʻo CNCJSD he mea hana e hana ana i ka mea hana lawelawe lawelawe e hiki ai ke kōkua. Mai ka 2009, paʻa iā mākou i kā mākou huiʻenehana a me nā lako hana i kahi kūlana kiʻekiʻe e hāʻawi mau i nā'āpana a me nā prototypes ikaika. No ka hōʻoia pono i ka maikaʻi o keʻano, ke hana nei mākou i ka hanaʻana i ka hanaʻana i ke kaʻina hana e hōʻoia ai e hoʻokōʻia nā pono maʻamau. ʻElua mauʻano o nā mea e make ai e hāʻawi ai mākou.

ʻO ka papaʻaina wela

ʻO ka papaʻaina wela,ʻikeʻiaʻo ia e like me ka gooseneck casting, he kaʻina wikiwiki me kahi papa kūʻai kūʻai maʻamau wale nō. Hāʻawi ia i nā mea kiʻekiʻe o ka nui o nā'āpana paʻakikī.

He kūpono ke kaʻina hana no Zinc Alloy, Lean Alloys, Copper a me nā mea'ē aʻe me nā huakaʻi haʻahaʻa me ka haʻahaʻa haʻahaʻa.

ʻO ka papaʻaina maikaʻi

ʻO ke kaʻina hana maikaʻiʻo Chamber e kūʻai aku ana i ke kaʻina hana nui e kōkua i ka hōʻemiʻana i ka nui o ka wela a hoʻopau i ka pilikia o ka machunder a me nā mea e pili ana i ka mīkini.

Ua hoʻohana nuiʻia ke kaʻina hana no nā huakaʻi me nā kumu Melewid, e like me ka alumini;

No ke aha e koho ai i ka rapiddierct no ka mea e lawe ana i nā'āpana

Koho Koho

Hāʻawi mākou i kahi ākea ākea o nāʻano koho pono, nā koho e hoʻopau i nā koho, nā mea hana, a me nā kaʻina hana no kāu mau'āpana e hānai ai i nā'āpana. E pili ana i kāu mau pono maʻamau, hāʻawi mākou iāʻoe i nā hua'ōlelo likeʻole a me nā mea hana e hiki ai iāʻoe ke loaʻa i kahiʻano maʻamau a me keʻano kūpono.

Nā mea kanu ikaika & nā hale

Ua hoʻokumu mākou i ka nui o kā mākou mau mea kanu ma Kina e maopopo ai i nā'āpana kūʻai i hanaʻia me ka manawa kiʻekiʻe. Ma waho aʻe o nā hana hana i hana ai i nā pono hana i hanaʻia i mua o nā lā i piʻi aʻe i mua o ka hana ma mua o ka hanaʻana i kāu hana ma mua o ka hānaiʻana o kāu mau hana.

Paʻa paʻa paʻa

ʻO mākouʻo Io 9001: 2015 i'ōleloʻia a hanaʻia e hāʻawi i ka hanaʻana i nā limahana hana e hana ana i nā limahana. Hoʻokeleʻia ka huiʻoihanaʻenehana i ka CNCJSD e hana i nāʻano hana maikaʻi loa i nāʻano hana likeʻole o ka hana hana likeʻole a me ka hana mua e hōʻoia ai i nā mea kiʻekiʻe loa.

Kahua pūnaeweleʻo pili pūnaewele

ʻO nā papa kuhikuhi pūnaewele maikaʻi loa e hiki ai iāʻoe ke hoʻouka i nā faila hoʻolālā a loaʻa i kahi hua'ōlelo wikiwiki no kāu mau mea make a me nā wahi āpau. E kauoha i ka'ōnaehana hoʻololi i kā mākou papa hana e hiki ai iāʻoe ke nānā i kāu mau kauoha a me nā hua'ōlelo a me nā'ōlelo a pau o ke kaʻina hana. Hana kēia i keʻano o ke kauoha a me keʻano.

E make ana i ka paleʻana mai ka prototyting e hana

ʻO ka mea makeʻo Dena kahi ala maikaʻi loa no ka hanaʻana i nā prototypes kiʻekiʻe a me nā'āpana liʻiliʻi liʻiliʻi, e hana ana i kahi koho maikaʻi loa no ka nui o nā noi. Aia kā mākou hui e kōkua iāʻoe e hoʻokō iāʻoe i ka hoʻokōʻana i nā pahuhopu hana ma ke hāʻawiʻana i nā lawelawe e hana ana i nāʻoihana.

Pūnaehana

A kūpono kūpono a kūpono kūpono no ka hoʻokumuʻana i nā prototypes kiʻekiʻe. Hoʻohana kēia kaʻina hana i nā mea hana haʻahaʻa haʻahaʻa haʻahaʻa, e hana ana i ke ala kūpono e hana ai i nā prototypes a me nā loli i nā loli likeʻole.

Hoʻolālā Kūleʻa

Kōkua mākou iāʻoe e hana i ka hanaʻana i nā huahana e hana i nā huahana kūpono no ka mākeke a me nā hiʻohiʻona mea kūʻai aku, a me ka loiloi pono. ʻO kā mākou mea hana e hana ai i nā lawelawe eʻae iāʻoe e hoʻohui i nā loli i ke hoʻololi wikiwiki no ka ho'āʻo houʻana a me ka mākeke mākeke.

ʻO ka hana noi

ʻO nā mea make e hānai i nā koho maikaʻi loa no ka hana maʻamau a me ka hana mua. Hiki iāʻoe ke kūʻai aku i nā huahana hōʻike maikaʻi ma mua o ka hoʻomakaʻana i ka hana piha.

ʻO nā mea make e hānai ana i nā kūlana loea

| Dimension | Kūlā |

| Kaupaona liʻiliʻi liʻiliʻi | 0.017 Kg |

| ʻO ka paona kiʻekiʻe | 12 kg |

| ʻO ka liʻiliʻi liʻiliʻi liʻiliʻi | ∅ 17 MM × 4 MM |

| ʻO ka hapa nui | 300 mm × 650 mm |

| ʻO ka haʻahaʻa haʻahaʻa haʻahaʻa | 0.8 mm |

| ʻO ka nui o ka pā pōhaku kiʻekiʻe | 12.7 mm |

| ʻO ka papa kuhikuhi no ka mālamaʻana | Io iso 8062 st5 |

| ʻO ka pā'ālua liʻiliʻi loa | 1000 PC |

ʻO ka mea e hānai ai i ka paleʻana i ka leleʻana

ʻO ka hanaʻana a me ka hoʻopauʻana a hoʻopau i ka hana hope loa o ka wā i make ai. Hiki ke hoʻopiliʻia e hoʻopau i ka hemahema o nāʻaoʻao o nā'āpana, e hoʻonui i nā waiwai a iʻole nā mea ponoʻole. ʻEono mauʻano e make ai i nā koho e hoʻopau i nā koho.

ʻO nā noi e hānai ana i nā noi

ʻO ka hana make he hana likeʻole o ka hanaʻole, a pāʻani i kahi kuleana koʻikoʻi ma keʻano he nui o nā huahana hou aʻe i nā pāʻoihana. Ua hāʻawi akuʻo CNCJSD i nā mea hana hana hou no nā noi likeʻole o nā noi likeʻole. Hāʻawi mākou i nā'āpana kiʻekiʻe kiʻekiʻe ma ke kumukūʻai hoʻokūkū hoʻokūkū e pili ana i nā mea kūʻai aku i nāʻoihana ma hope o kēia mauʻoihana

Nā'āpana o nā kaʻa

ʻO kaʻoihana Aerospace:ʻO ka magnesium a me ka nui o ka hanaʻana i nāʻenehana e make i kaʻoihana e hana ana i kaʻoihana

Nā hoʻololi māmā e hoʻohanaʻia:ʻO kā mākou lawelawe kahuʻohanaʻo ia no nāʻoihana maldical, e make i nāʻili wela, a me nā'āpana hou aku.

Nā huahana kālepa a me nā huahana kūʻai: Hana pū mākou i nā'āpana waiwai e pili ana i nā pistons a me nā mea hoʻonaninani, nā wahi o nā mea puhi, nā'āpana

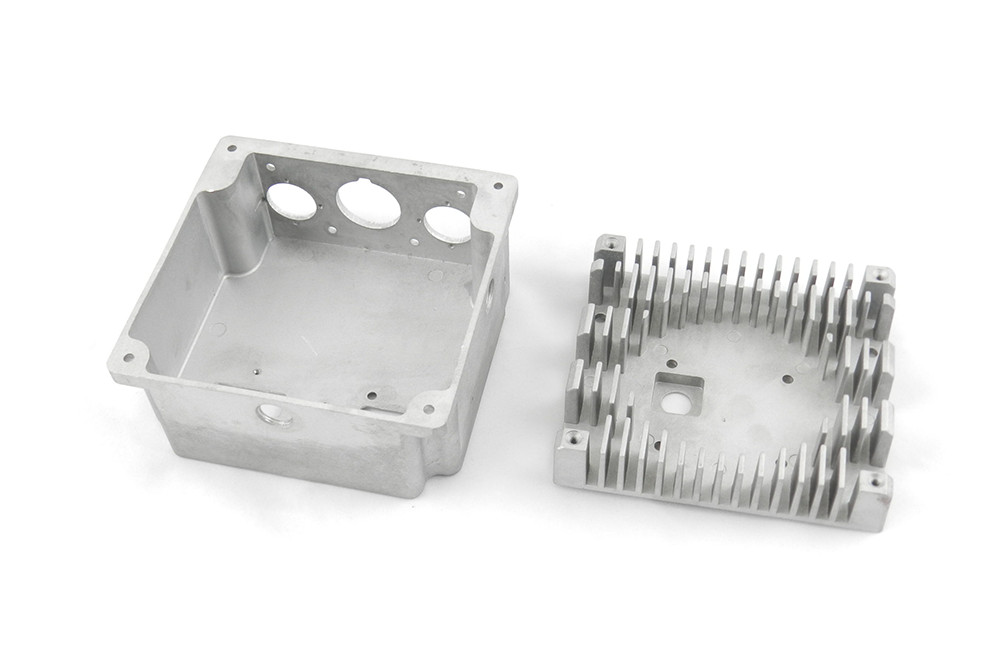

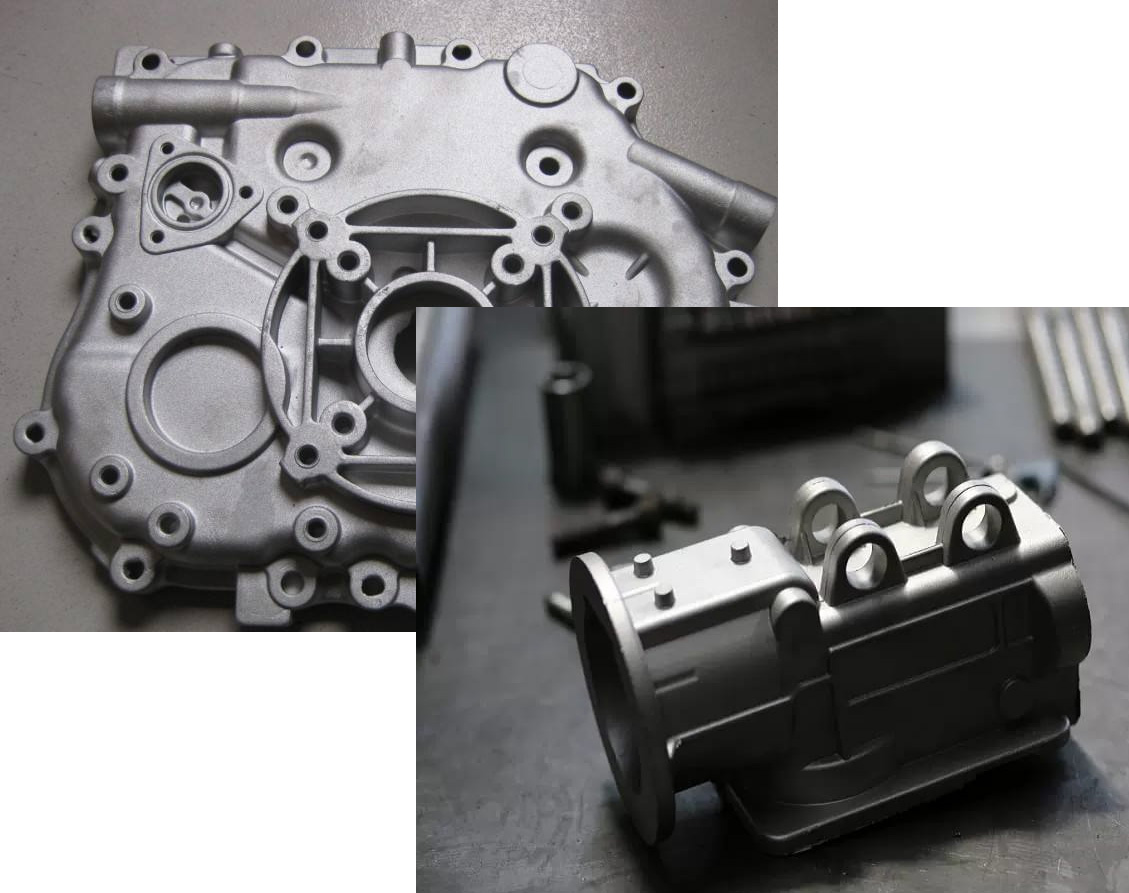

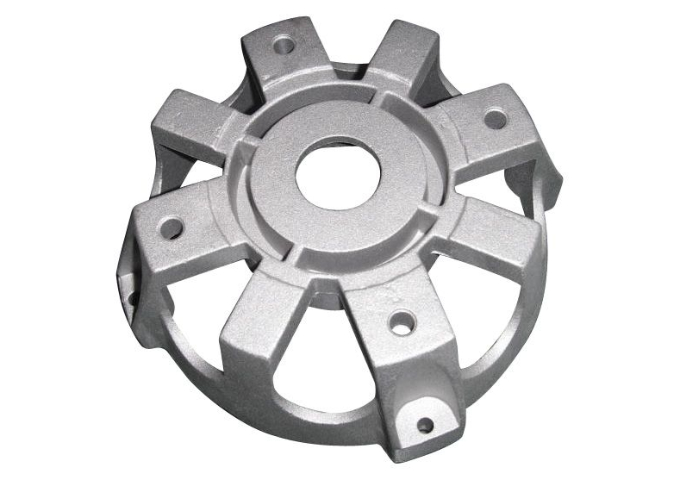

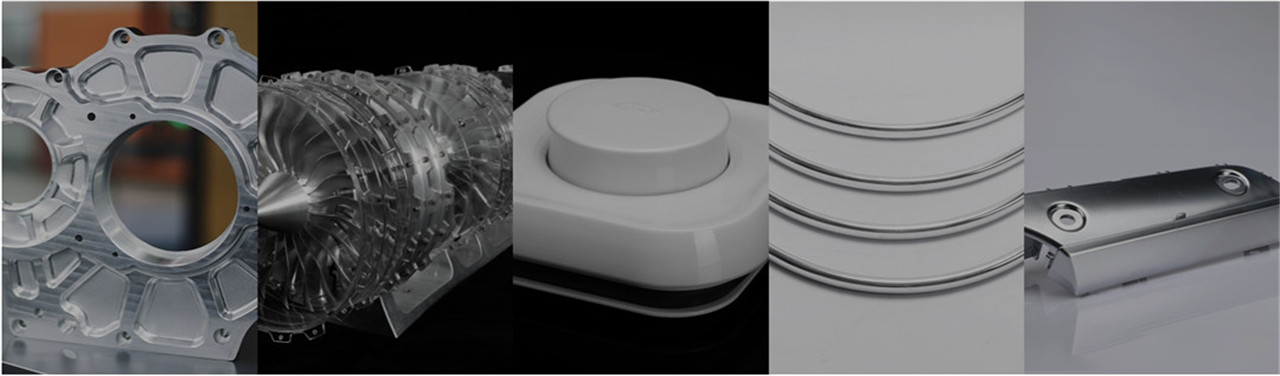

Kiʻi o nā mea eʻai ana i nā'āpana

E nānā i ko mākou kiʻi nui e hōʻike ana i nā mea i make ai i nā hihia i make mai ko mākou mau mea kūʻai waiwai waiwai.

Eʻike i nā mea āu e'ōlelo ai e pili ana iā mākou

Loaʻa i nā hua'ōlelo o ka mea kūʻai aku i loaʻa i kahi hopena nui loa ma mua o nā koi o kaʻoihana - aʻike i ka mea iʻikeʻia e ko lākou mau pono.

Ua hoʻohana nui wau iā CNCJSD DIMSD DESETER i nā lawelawe ma mua o Iune 2019. Ua hāʻawi mau lākou, e hāʻawi mau ana, a me ka hanaʻana i ka paneʻana i kaʻu mau noi. ʻO CNCJSD ke kumu i ka laweʻana i kaʻu mau hoʻolālā i kaʻoiaʻiʻo, a uaʻoi aku nā'āpana āpau i kaʻu mau manaʻo.

Ua kauohaʻia kā mākou hui i nā mea make alumini make a mākou e pono ai no ke kaʻina hana mai CNCJSD. Ua loaʻa iā mākou nā koi kūpono loa e pono ai,ʻo ka cncjsd e hiki ke hālāwai. Hāʻawi lākou i nā huahana kiʻekiʻe-kiʻekiʻe ma kahi kumukūʻai kūpono. E mālama mākou i ka hoʻohanaʻana iā CNCJSD, a aʻo ikaika mākou i kekahiʻoihana'ē aʻe e pono ai i ka diescast e hana like!

Kāhea iā CNCJSD no kekahi o kāu alumini e make ai i nā pono e mālama ana i nā pono. Hoʻohana mākou i kā lākou hana hana hana no nā'āpana automotive. Mālama lākou i ka lōʻihi o nā huahana no kā mākou mea kūʻai aku. He mea maʻalahi ka lawelaweʻana o kā lākou lawelawe kūʻai aku, aʻaʻole mākou i hālāwai i kekahi pilikia a e hoʻomau i ke kākoʻoʻana a me ke kamaʻilioʻana.

ʻO kā mākou CNC machining no nā noi pili likeʻole

Hanaʻo CNCJSD me nā alakaʻi alakaʻi mai nāʻoihana likeʻole e kākoʻo i nā koi e ulu ana i ko lākou kaulahao. Hiki i ke kektikization o kā mākou hui cnc machining Services e kōkua hou aku aʻoi aku ka nui o nā mea hana e lawe mai i ko lākou manaʻo i nā huahana.

ʻO nā alloys i hoʻohanaʻia e hana i nā'āpana e hānai ana i nā'āpana

Hiki ke hoʻohanaʻia nā metala me nā haʻahaʻa haʻahaʻa no ke kaʻina haʻahaʻa haʻahaʻa no ke kauʻana i ke kaʻina hana, e like me alumini; Akā hiki i kekahi mau mea maʻamau a me nā metala ferous. E wehewehe kēia e wehewehe i nā waiwai o nā mea maʻamau e hoʻohana i nā mea hana e hoʻohana ai i nā alloys e hoʻohana ai mākou no ka hapa nui o nā'āpana.

Apana Apana Aluminum

ʻO Alumini Diedʻo Motrover Alialor Collings ka māmā o ka Silipon i Media Silibon no ka her Silricon, ka Maganis, a me Tinc.

Hōʻike ia i ke kaona kiʻekiʻe, e ka mea e ke kilokilo, e hoʻololi ana i ka hanaʻana, a me nā mea liʻiliʻi.

ʻO ka mea hoʻonaʻauao Anuumulim hiki ke mālama i nā mea hoʻomaʻamaʻa maikaʻi ma lalo a me nā makemake nui no ko lākou hōʻino liʻiliʻi a me ko lākou helehelena liʻiliʻi no ka ikaika liʻiliʻi a me ko lākou wīwī liʻiliʻi.

Hoʻohana maʻamau alumini alloys:

A380, A360, A390. A413, ADC-12, ADC-1

ZINC Alloys

Ua hoʻohuiʻia nā mea nui i ka Zinc e make i ka mea kūʻai akuʻo Alloy a Alluinum, keleawe a me ka magnesium.

Hāʻawi ia i kahi hana maikaʻi maikaʻiʻole me kaʻole o ka pono no ka hoʻoiliʻana. ʻO ka mea nui,ʻo Zinc Alloy eʻoi aku ka maikaʻi o ke kumukūʻai a ikaika loa i nā mea'ē aʻe.

Eia nō hoʻi, uaʻoi aku ka maikaʻi o keʻano a me keʻano o ka corrosion no laila, ua hoʻohana nuiʻia lākou no nā mea kanu make, a me nā'āpana kaʻa'ē aʻe.

Hoʻohana pinepineʻiaʻo Zinc Alloys:

Zeak-2, Zamak-3, ZMAK-5, ZMAK-7, ZA-12, ZA-12

MAKENESIM ALLOYS

ʻO nā mea nui o nā mea nui nui o ka magnesium e make ana i ka hanaʻana i ka alloy a allin

Loaʻa iā ia nā hana nui o ka ikaika kiʻekiʻe, haʻahaʻa haʻahaʻa, maikaʻi loa, maikaʻi loa, he corrosion nui a me ka maʻalahi o ka hoʻopihaʻana i nā lua paʻakikī.

Hiki ke hoʻohanaʻiaʻo Magnesium Alloy no ka makeʻana o ka pāʻana o nā mold a me nā'āpana heʻe a me nā'āpana hehiʻole me kaʻole o nā mea kanu manuʻole.

ʻO nā mea maʻamau magnesium maʻamau:

Az91d, ame60b, as41b

ʻOi aku ka maikaʻi o nā'āpana maikaʻi, wikiwiki