30T-1800T

Inji moling

12

Saman gama

0pc

Moq

0.05mm

Haƙuri

Abubuwan da muke so

Daga sahihiyar filastik don samarwa, CNNCHSD sabis na al'ada allurar rigakafin tsari yana da kyau don masana'antar farashin gasa, ingantattun sassan molds a cikin sauri. Kayan masana'antu masu ƙarfi tare da ƙarfi, injunan machines suna tabbatar da kayan aiki iri ɗaya don ƙirƙirar sassa masu daidaito. Zai fi kyau, muna ba da shawara game da kowane tsari na allurar rigakafi, ciki har da shawarar ƙirar ƙira, kayan da kuma hanyoyin ƙarewa don aikace-aikacen da kuka ƙare, da hanyoyin jigilar kaya.

Filastik inurarsa

Tare da kwarewarmu da kayan aikinmu, muna da kyau a cikin zane da masana'antu seri jerin abubuwan allurar filastik masu ƙyalƙyali da tsada.

Filastik allurar motsa jiki

Tsarin allurar mu na sarrafa kayan aikinmu yana amfani da madaidaicin injin don harba molten molten a cikin molten ya zama babban metrmoplastic kashi.

Ban mamaki

Rufe filastik, ƙarfe, da kuma roba akan juna ta hanyar haɗin sunadarai, abubuwan da muka yi na rage yawan taro kuma suna ba da ƙananan ƙarfinmu da sassauƙa.

Saka Mold

Saka abin da aka gyara shine aiwatar da kayan aikin thermoplastics a kusa da abin da aka riga aka gama don ƙirƙirar ɓangaren da aka gama.

Mutu jefa daga m zuwa samarwa

Dubi yadda muke aiwatar da umarnanka, daga ambato don kayan aiki, kamar yadda ƙungiyarmu da ingantattun ƙungiyar da ke tabbatar da cewa kun sami mawuyarku da sassan da aka shirya.

Nemi don magana

Nemi naka daga dandalin ambaliyarmu da injiniyan da aka yi da aka keɓe zasu samar da amsa a cikin sa'o'i 24, tabbatar da tsari yana ci gaba da kyau.

Rahoton DFM

Don tabbatar za mu iya samar da molds na aiki, muna yin cikakken bayani game da ƙirar ku don tabbatar da cewa zamu iya biyan buƙatu kafin fara samarwa.

Binciken tsintsiya

Manhajar somayar yi ta taimaka mana a kan hanyar molten abu motsawa da kuma aiwatar da su, wanda yake taimaka mana mu isar da cigaba.

Ingantaccen Kayan Kayan Aiki

Fara samar da kayan aikin kayan aikin gawa gwargwadon takamaiman aikace-aikacen ku ta amfani da kayan da kuma gamsuwar da kuka zaɓi.

T1 Tabbatar da samfurin T1

Za'a gabatar da t1 spaming a gare ku don yin bita kafin masana'antun filastik don tabbatar da daidaito da inganci.

Low samar da girma

Bayan kammala lokacin samarwa na gwaji, zamu ci gaba zuwa samar da karawa, muna amfani da dabarun sarrafa inji don ƙirƙirar sassan da sauri da yadda yakamata.

Binciken tsayayyen dubawa

Tsarin bincike mai tsayayye, gami da binciken aiki, girma, da bayyanar, yana tabbatar da cewa sassan suna biyan dalla-dalla da ake buƙata kuma suna da inganci.

Ceto

Bayan ingantaccen bincike, zamu isar da samfuran ku a cikin sauri yayin da zai tabbatar da amincin su.

Allurar rigakafi daga fastocin zuwa samarwa

Cigera ya mutu shine ingantacciyar hanya mai inganci don samar da mahimman bayanan abubuwa da ƙananan abubuwa, yana sa shi kyakkyawan zaɓi don ɗakunan aikace-aikace. Teamungiyarmu ta zo ne don taimaka muku wajen cimma burin kamfanonin ku ta hanyar samar da sabis na masanan kashe kashe masana sayen mutane.

Kayan aiki

Sami cikakken bayani da inganci ta hanyar kayan aikin ingantaccen tsari. Newirƙiri ƙananan samari na filastik masu filastik da kyakkyawan yanayin allurar rigakafi. Mun fi dacewa da masana'antu samfurin prototype a cikin kwanaki don tabbatar da cewa kun cika gwaje-gwaje aiki da inganta ƙwarewar kasuwa.

Kayan aiki

Mun kirkiro da ingancin samar da ingantaccen inganci don samar da filayen filastik na manyan filastik. Tare da ƙarfi-ƙarfi, mai dorewa kayan aiki na samarwa ya dace don samar da daruruwan dubban sassa. Zamu iya bambanta kayan da hanyoyin gini bisa ga buƙatunku na musamman.

Cncjsd allurar gyada

| Ƙa'idoji | Siffantarwa |

| Matsakaicin sashi | 1200 × 1000 × 500 mm47.2 × 39.4 × 19.7 a. |

| Mafi qarancin sashi | 1 × 1 × 1 mm0.039 × 0.039 × 0.039 a. |

| Bangare zuwa wani maimaitawa | +/- 0.1 mm+/- 0.0039 a. |

| Mold lityvity haƙuri | +/- 0.05 mm+/- 0.002 a ciki. |

| Akwai nau'ikan molds | Karfe da kayan aiki na aluminum. Ranar samarwa muna samarwa: A ƙarƙashin hawan keke 1000, a ƙarƙashin hawan keke 5000 |

| Injin da akwai | Rami mara nauyi, da yawa, da molds,50 zuwa 5 latsa Tonnage |

| Ayyukan sakandare | A cikin rubutun hannu, bugu na pad, allon lergra, da aka buga da aka yiwa da Majalisar Dinkin. |

| Dubawa da zaɓuɓɓukan sanarwa | Tarihin Darasi na farko, ISO 9001, iso 13485 |

| Lokacin jagoranci | 15 kwanakin kasuwanci ko ƙasa da yawancin umarni,24/7 ambaton amsa |

Class na alluna gyara morm

A CNCJSD, muna tsara kuma muna ƙirƙirar madaidaicin madaidaicin allurar al'ada ta al'ada daga kayan inganci. Hanyoyinmu suna tabbatar da daidaito da maimaita ruwa a cikin saurin jagoranta da farashi mai araha. Kowane allurar filastik da muke ƙirƙira mun ƙirƙira haduwa da ka'idodi na duniya. Daga ayyukan daya zuwa kananan batches da kayan aikin samarwa, muna ba da dorewa da ingantattun kayan aikin.

| Mold aji | Nufi | Harshen harafi | Haƙuri | Kuɗi | Lokacin jagoranci |

| Aji 105 | Gwajin Proton | A karkashin 500 Hycles | ± 0.02mm | $ | 7-10 kwana |

| Aji 104 | Samar da karami | A karkashin 100.000 Hycles | ± 0.02mm | $$$ | 10-15 days |

| Aji 103 | Samar da karami | A karkashin 500.000 Hycles | ± 0.02mm | $$$$ | 10-15 days |

| Class 102 | Tsarin girma na matsakaici | Matsakaici zuwa babban samarwa | ± 0.02mm | $$$$$ | 10-15 days |

| Aji 101 | Babban girma | Sama da 1,000,000 hawan keke | ± 0.02mm | $$$$$$ | 10-18 days |

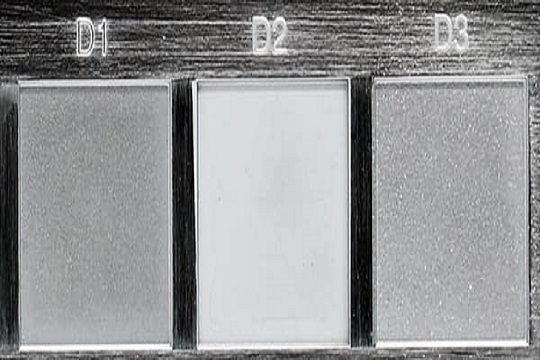

Farfajiya ta ƙare da allurar rigakafi

Abubuwan da ake ciki na allurarsa sun haɗa da kayan aikin shiriya, kayan allura filastik, da ƙari. A farfajiya na mold yawanci an gama shi yayin aiwatar da samarwa. Bayan an kammala gyaran allura, zamu aiwatar da wasu jiyya a kan abin da aka gama kamar yadda kake bukata.

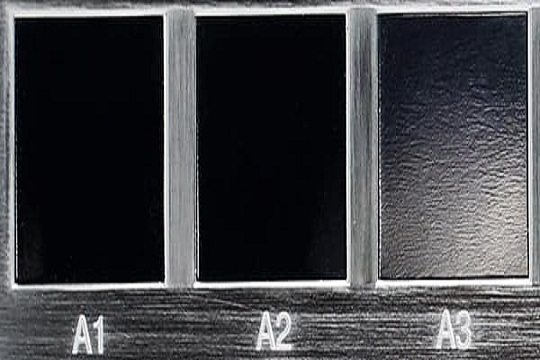

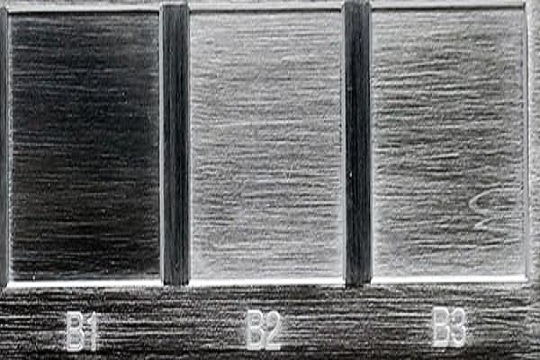

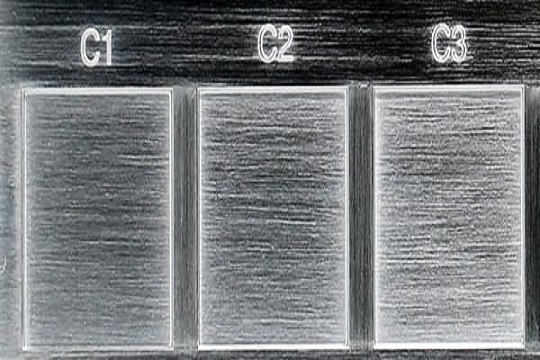

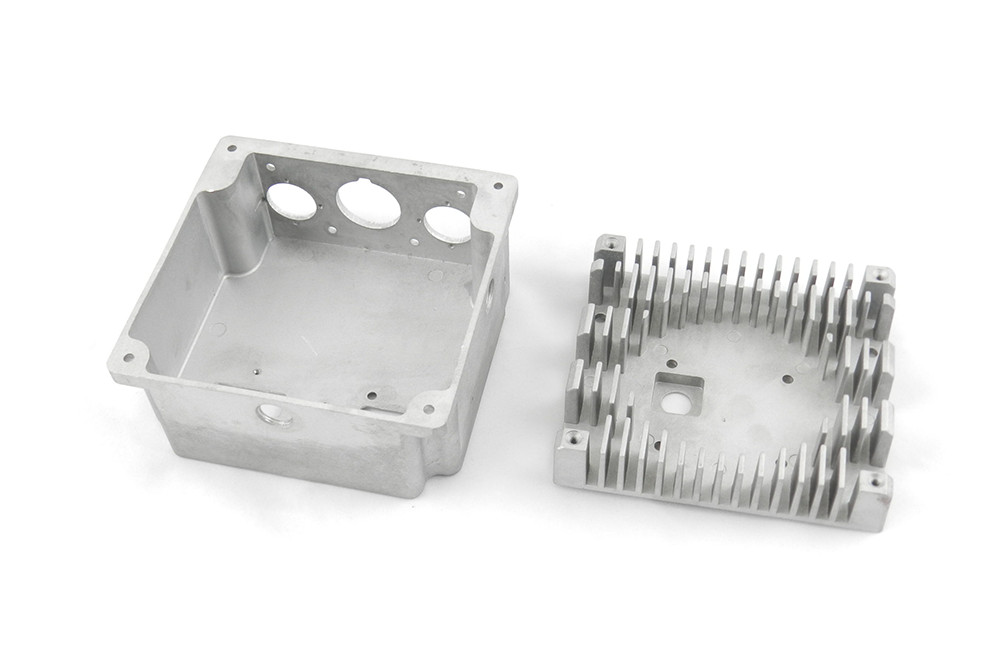

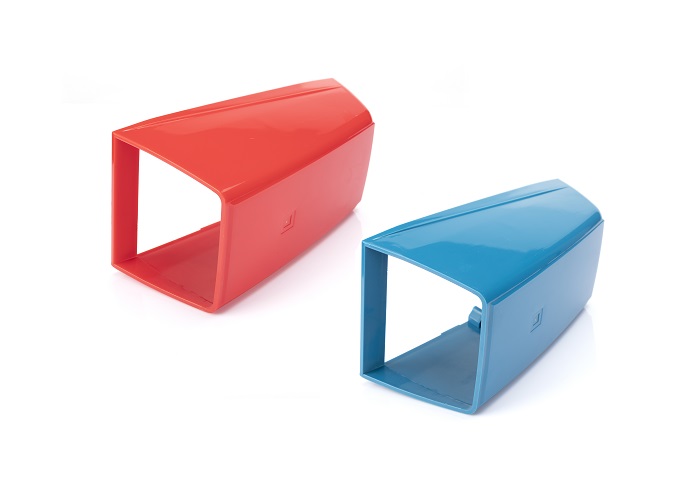

Gallery na kayan ado na allurar rigakafi

Rarraba cikin CNNCJsd mai yawa gallery wanda ke nuna wasu daga cikin abubuwan allurarmu da aka kammala kuma za mu iya kirkirar aikin da kuka daidaita a gwargwadon bayanan dalla-dalla.

Me yasa Zabi CNCJsd don Ayyukan Alli na al'ada

Babu moq

Babu mafi karancin oda bukatar taimaka Mold sassan filastik da sauri don samarwa a cikin kayan aikin da aka yi amfani da shi da kuma tallafawa masana'antun da aka yi amfani da shi tare da rage farashin kayan kwalliya.

Babban inganci

Tare da ingantaccen masana'antu na gida da kuma tsarin sarkar samar da samfur, muna hanzarta sake zagayowar samfurin samfuri kuma gada da samar da sassan abubuwan da kuke so a cikin sauri kamar yadda zai yiwu.

Daidaito da ingancin inganci

Owing Tabbatattun masana'antu, gudanar da bincike na aiwatarwa da tabbataccen tabbaci bayan samarwa, bada garantin al'adar al'ada suna daidaito a cikin ingancin ba tare da la'akari da tsarin hadaddun.

'Yan Sanda

Aiki tare da ƙwararrunmu suna da shekaru 10+ shekaru 10+ na masana'antar da ke cikin allura, rijiyar yadda aka kammala juyawa daga prototy zuwa samarwa.

Shirya don samun kwatancen halayenku na al'ada?

Koyi abin da kuke buƙata kafin neman maganganu don ayyukan da kuka daidaita ayyukansu a CNCJSD. Taimaka muku samun sassa masu ban mamaki da aka yi da kyau, cikin sauki.

Dubi abin da abokan cinikinmu suka ce game da mu

Kalmomin abokin ciniki suna da ƙarin tasiri fiye da da'awar kamfani - kuma ga abin da abokan cinikinmu suka gamsu sun faɗi game da yadda muka cika bukatunsu.

CNCJSD ya kasance abokin tarayya na Molding na tsawon shekaru 2. Tun daga wannan lokacin, CNCjsd ya ba mu damar da sassan-bahold da aka gyara ba. Bugu da kari, CNCJsd ya ba da sabis na taro don samfuran da aka tsara masu yawa na mu har zuwa samfurin ƙarshe na ƙarshe. Na yi farin cikin bayar da shawarar CNCJsd ga kowa yana neman samfuran-bahold da aka gyara.

Ma'aikatan a CNCJsd ya taimaka mana wajen jaddada ra'ayoyinmu cikin sassan da aka gama tsawon shekaru a yanzu. Harkar daga ciki a cikin masana'antu ya zama santsi, godiya ga iliminsu, ƙwarewarsu, da "iya-yi" hali. Wannan na daya ne daga cikin kawancen kasuwanci na kasuwanci na kasuwanci saboda CNCJSD mai mahimmanci akan gamsuwa na abokin ciniki.

CNCJSD ya tabbatar da cewa za ta zama babban mai samar da kayan adon da aka gyara don kamfaninmu. Sun yi mana fatansu koyaushe tare da mu koyaushe, adalci, da farashin da suka dace. Mun dauki hayar CNC don ƙirƙirar molds a gare mu, gyara da daidaita abubuwan da ake buƙata don dacewa da bukatunmu, kuma ku sadu da abubuwa waɗanda suka dace da ƙayyadaddun bayanai.

Motocin CNC na CNC don aikace-aikacen masana'antu daban-daban

CNCJSD yana aiki tare da manyan masana'antun daga masana'antu daban-daban don tallafa wa buƙatun ci gaba da kuma jera sarkar samar da sarkar su. Digitalization na ayyukanmu na al'ada CLN sabis yana taimakawa ƙarin masana'antun da ke kawo ra'ayinsu ga samfuran.

Kayan don allurar gyara

Waɗannan sune abubuwan da aka saba da farfadowa da sabis ɗin da muke da shi na bayar da shi. Bayan sanin kayan yau da kullun, kamar maki na gama gari, alamomi, fa'idodi, zabi kayan moldi na dama dangane da bukatun aikace-aikacenku.

Kayan aiki kayan aiki

Kafin tsari mai narkewa na tsari yana farawa ko babban-girma girma, ana buƙatar kayan aiki mai kyau CNC. Mafi yawan abubuwan da aka saba amfani sun hada da:

Kayan Aiki: P20, H13, S7, Nak80, S136, S136H, 718H, 738, 738, 738

Bakin karfe: 420, Nak80, S136, 316l, 316, 303, 303

Aluminia: 6061, 5052, 7075

Kayan filastik

Filastik na kayan aikin filastik yana zuwa tare da kewayon kayan da yawa tare da kaddarorin daban-daban, gami da karfin tasiri, tsauri, juriya, juriya na sinadarai, da sauransu.

| Abin da | Nylon (pa) | PC | PVC |

| PU | Hula | PP | Ƙafa |

| PE | Hdpe | PS | Yi shelar alkjjada |

Ƙari da zaruruwa

Kayan kayan aiki na yau da kullun bazai cika bukatun kayan haɗin ƙirar allurar rigakafi ba. A wannan yanayin, ƙari da ƙobures za a iya ƙara don haɓaka haɓaka da kayan aiki na aiki, samar da ƙarin fasalulluka don ɓangarorin da kuka yi.

| UV Masu Zamani | Gwaloli |

| Harshen Rage | Gilashin Gilashi |

| Filastik |

Sassa masu inganci ya sauƙaƙa, da sauri