24h

Rapid quotes

10 days

Lead time

0pc

MOQ

0.010 mm

Tolerances

Our Precision Die Casting Services

If you have needs of custom metal parts, cncjsd is a die casting service manufacturer that can help. Since 2009, we’ve hold our engineering team and equipment to a high standard to continually deliver strong and durable parts and prototypes. To ensure legendary quality, we operate strict die casting process that ensures that your custom requirements are being met. These are two types of die casting capabilities we provide.

Hot Chamber Die Casting

Hot chamber die casting, also known as gooseneck casting, is a considerably quick process with a typical casting cycle only 15 to 20 minutes. It allows for high volume manufacturing of comparatively complex parts.

The process is ideal for zinc alloy, lean alloys, copper and other alloys with low melting point.

Cold Chamber Die Casting

Cold chamber die casting process is an very important procedure which helps reduce the amount of heat and solve the corrosion problem in machine’s plunder and related components.

The process is primarily used for alloys with high melting points, like aluminum, magnesium, some copper, and ferrous alloys.

Why Choose RapidDierct for Die Casting Parts

Extensive Selections

We provide a wide range of possible material types, surface finish options, tolerances, and manufacturing processes for your die casting parts. Based on your custom needs, we offer you different quotes and manufacturing suggestions so that you can get an individual approach and the most cost-effective solution.

Powerful Plant & Facilities

We have established numerous of our own plants in China to make sure your casting parts are manufactured with high efficiency and fast lead time. Besides, our manufacturing capabilities take advantage of up-to-date and automated facilities that can support an assortment of your customized die casting projects, though their designs are complicated.

Strict Quality Control

We are ISO 9001:2015 certificated company and committed to providing precision die casting services. Dedicated engineering team of cncjsd operates rigorous quality inspections in different stages of the manufacturing process: pre-production, in-production, first article inspection and before delivery to ensure the highest quality parts are manufactured.

Online Quotation Platform

Advanced online quoting platform to enable you to upload design files and get a fast quotation for your die cast metal parts anytime and anywhere. Order tracking system on our platform allows you to monitor all of your orders and quotes and view each stage of the manufacturing process once you place orders. This makes the order process clear and transparent.

Die Casting from Prototyping to Production

Die casting is a highly effective method for producing top-quality prototypes and small-batch parts, making it an excellent choice for a wide range of applications. Our team is here to assist you in achieving your manufacturing objectives by providing expert die casting services.

Prototyping

And affordable and efficient method for creating high-quality prototypes. This process utilizes low-cost tooling, making it a cost-effective way to produce prototypes with various materials and design changes.

Market Testing

We help you create die casting products ideal for market and consumer testing, concept models, and user evaluation. Our die casting services allow you to incorporate changes quickly for further testing and market launch.

On-Demand Production

Die cast parts are excellent options for custom and first-run production. You can cost-effectively test product quality before starting full-scale production.

Die Casting Technical Standards

| Dimension | Standards |

| Minimum part weight | 0.017 kg |

| Maximum part weight | 12 kg |

| Minimum part size | ∅ 17 mm × 4 mm |

| Maximum part size | 300 mm × 650 mm |

| Minimum wall thickness | 0.8 mm |

| Maximum wall thickness | 12.7 mm |

| Tolerance class for casting | ISO 8062 ST5 |

| Minimum possible batch | 1000 pcs |

Die Casting Surface Finishes

Post-processing and finishing is the final step of precision die casting. Finishing can be applied to remove the surface defects of cast parts, enhance mechanical or chemical properties, and improve products’ cosmetic appearance. There are six types of die casting surface finish options.

Die Casting Applications

Die casting is a versatile manufacturing technique, and it plays an important role in creating and producing many modern products, from aerospace structural parts to electrical enclosures. cncjsd has provided innovative manufacturing solutions for different industrial applications. We offer high quality parts at competitive pricing to value customers in the following industries:

Automotive Parts: As die cast parts manufacturer, we specialize in making vehicle parts like gears, cylinders, gladhands, transfer cases, small engine parts, and even components for lawn and garden tractors.

Aerospace Industry: Magnesium and aluminum pressure die casting technologies from precision die casting service can produce light, durable structural parts with great resistance to corrosion.

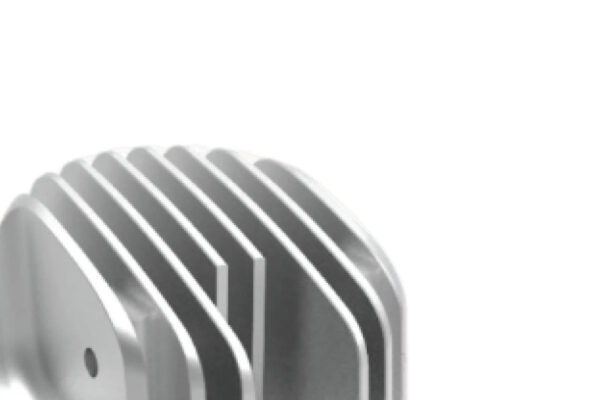

Lightning Components: Our die casting service is also for electrical housings, die cast heat sinks, and many more components.

Commercial & Consumer Products: We also manufacture commercial parts including compressor pistons and connecting rods, heat sinks, bearing housings, parts of the sink faucet, meters.

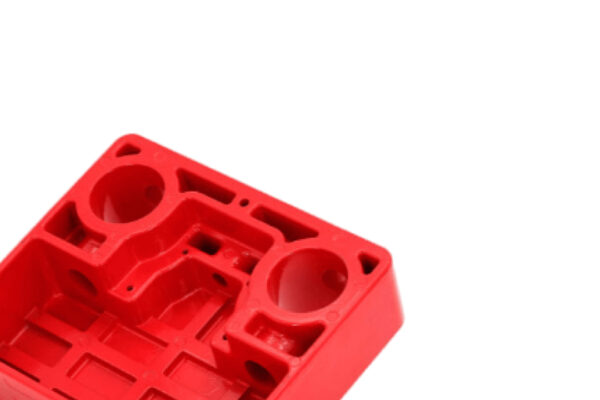

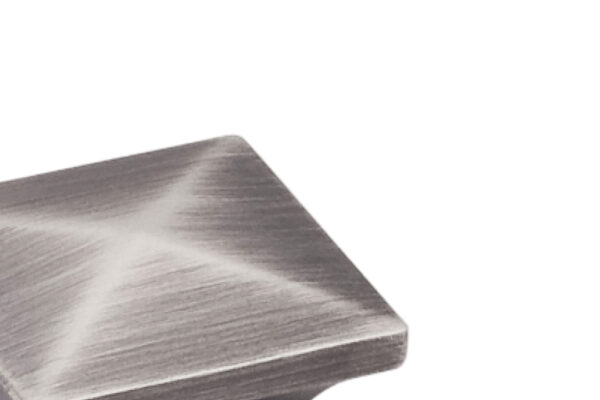

Gallery of Die Casting Parts

Check out our extensive gallery that shows precision die casts from our valued customers.

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

I have used cncjsd die casting services since June 2019. They have always been responsive, proactive, and professional in responding to my requests. cncjsd is instrumental in bringing my designs to reality, and every part exceeds my expectations.

Our company ordered aluminum die casts we need for an assembly process from cncjsd. We have highly precise manufacturing requirements, which cncjsd is able to meet. They provide high-quality goods at a reasonable price. We will keep using cncjsd, and we strongly advise any other company that requires diecast to do the same!

Contact cncjsd for any of your aluminum die casting needs. We use their manufacturing line for automotive parts. They guarantee the longevity of products for our customers. Their customer service was easy to reach, and we haven’t encountered any problems and will keep supporting and referring.

Our CNC Machining for Various Industrial Applications

CNCjsd works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom CNC machining services helps more and more manufacturers bring their idea to products.

Alloys Used to Make Die Casting Parts

The non-ferrous metals that have low fusing temperature can be used for the die casting process, like aluminum, zinc, magnesium, lead, copper. But some uncommon and ferrous metals are also possible. The following will explain the properties of the commonly used die casting alloys that we use for the majority of parts.

Aluminum Alloys

Aluminum die casting alloy is lightweight structural metal mainly containing silicon, copper, magnesium, iron, manganese, and zinc.

It exhibits high thermal conductivity, electrical conductivity, cutting performance, and small linear shrinkage, making it has excellent casting performance and filling ability.

Moreover, aluminum alloys can maintain good mechanical properties under high or low temperatures because of their small density and high strength.

Commonly used Aluminum alloys:

A380, A360, A390. A413, ADC-12, ADC-1

Zinc Alloys

The main elements added to zinc die casting alloy are aluminum, copper and magnesium.

It provides a good surface finish without the need for secondary processing. Importantly, zinc alloy is more cost-effective and stronger than other comparable alloys.

Also, it has better fluidity and corrosion resistance so they are mainly used for die-casting meters, automotive parts housings, and other complex metal parts.

Commonly used Zinc alloys:

Zamak-2, Zamak-3, Zamak-5, Zamak-7, ZA-8, ZA-12, ZA-27

Magnesium Alloys

The main alloying elements of Magnesium die casting alloy are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

It has the advantages of high strength, low viscosity, good fluidity, great corrosion resistance and easy filling of complex cavities.

Magnesium alloy can be used for die casting of mold and thin-wall parts without thermal cracks.

Commonly used Magnesium alloys:

AZ91D, AM60B, AS41B

Quality Parts Made Easier, Faster